From the moment the wheel came into existence, people have been faced with the seemingly simple task of mounting their inventions to a shaft so that something useful could be accomplished.

Within an industrial scenario, such as in a recycling plant, components such as couplings, pulleys, sprockets and flywheels need to be effectively connected to a shaft in order to transfer the torque.

The choice of the right shaft connection technique could determine how well the forces are transferred and how efficiently and smoothly the operations run.

Some of the more traditional shaft connection methods, including keyed and splined connections, while quite widespread, have certain limitations, according to Donald Brierley, who is the manager of FPT Far East Pte Ltd – a subsidiary of Inenco Group.

“Using a keyed connection has some limitations. Because you have to do some machining and cut the shaft for the key to fit in, you are basically reducing the shaft’s cross section. This makes the shaft weaker and you need to make adjustments in the original design, which often leads to a bigger shaft cross section being used,” he explains.

“Similarly, splined connections need many notches to be machined on the shaft, which increases the manufacturing cost and time and also increases the risk of cracking around the notches,” he adds.

To avoid these limitations, Brierley recommends using keyless locking devices, such as the Trantorque keyless bushings manufactured by Fenner Drives, where speedy installation and compact designs are needed.

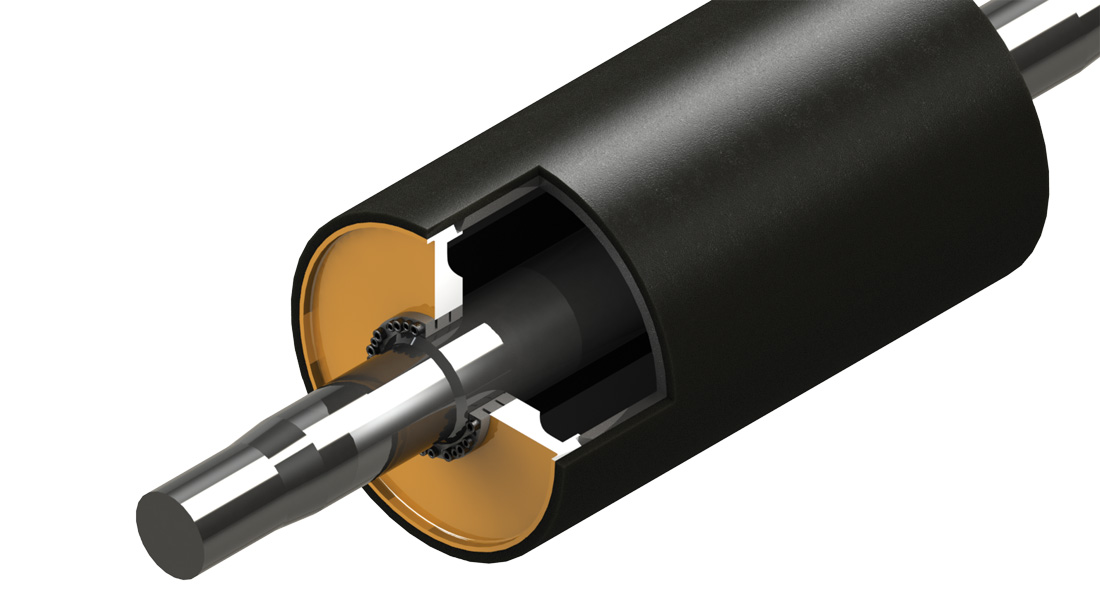

Keyless locking devices use locking screws and tapered rings to lock the components on to the shafts. There are a number of advantages in using a keyless mechanism, says Brierley.

“Keyless locking devices do not need any notches to be machined on to the shaft. This means you can use the full cross section of the shaft, which is more economical. Also, because you don’t need to machine a key, the processing time is reduced,” he explains.

Another advantage of using keyless locking bushings is the shorter installation time, he says.

“Using keyless bushings reduces the time needed for aligning the coupling or pulley during installation. Also, all of the screws on the Trantorque bushings can be tightened using a single spanner, which also makes the installation faster,” he says.

Lower vibration is another key consideration with a number of applications in recycling. Vibration in the shaft connection is often caused by imbalanced weight as a result of the keyed section. But because keyless connections such as Trantorque have a uniform diameter, Brierley says vibrations are significantly reduced.

Fenner Drives’ Trantorque bushings can accommodate shaft sizes from 1/8 inch (3 millimetres) up to 3 inches (75 millimetres) and are available for both metric and imperial shaft sizes. The locking devices are also available in the stainless-steel range or with anti-corrosion coatings, which makes them suitable for aggressive environments in recycling plants.

Steve Hittmann, who is the National Product Manager of Mechanical Drives at CBC Australia, says these advantages make Trantorque keyless bushings the connection device of choice for a number of original equipment manufacturers.

“One of our customers is a manufacturer of agricultural machinery that uses Trantorque bushings to connect hydraulic motors to driven shafts. The customer required an imperial shaft device of one-inch diameter and had a restricted envelope to work with. Because Trantorque locking devices are compact in design, they were a perfect fit,” says Steve.

“Moreover, using Trantorque enabled the hydraulic motors to be installed concentrically and with the convenience of a uniform mechanical fit,” he explains.

Apart from being the exclusive distributor of Trantorque bushings in Australia, Steve says the CBC technical team can also respond to any enquiry from the customers regarding the right design.

“When we get an enquiry from a customer, we often help them with the selection of the right locking device. When needed, we also work with Fenner Drives to assist with designing the technical specifications,” says Steve.

“This gives our customers the comfort to order what they need when they need it, knowing that we will support them every step of the way,” he concludes.