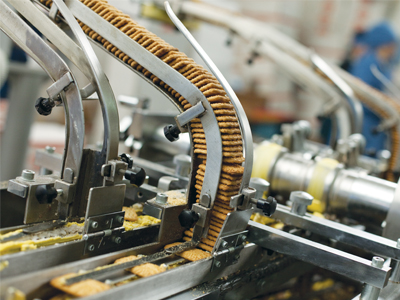

Contamination of food and beverages during manufacturing is always in the back of the mind of those who run the processing factories. At any time during course of making product, plant and machinery could accidentally contaminate the goods, so it is important that best practices are in place once a production run is started.

And while best practices are a good start in keeping food and beverage items free from contaminants, there are some items that can help provide layers of protection during the production process itself.

According to precision mechanics specialist NTN-SNR, the average cost worldwide for product recalls in the food processing industry between 2010 and 2017 was just over $16 million. The most common reasons were foreign bodies found in the product, and contamination by allergens and/or bacteria. With that in mind, the company has produced LP09, a food-grade solid grease that lubricates bearings that are used in the food processing industry. It is designed to give food and beverage processors peace of mind if they are worried about bearing grease contaminating the production line. This particular grease is approved by NSF International, a US-based independent product testing, inspection and certification organisation.

“When you test your product and you find it is contaminated by foreign matter, that food needs to be scrapped and cannot be sold,” said Fabio Rebecchi, who is product manager for NTN-CBC Australia who distributes LP09 in Australia. “One of those contaminants could be grease. Can you imagine how much that could cost a company if it fails its compliance?

“However, if a food product makes contact with LP09 solid grease, that’s fine because it complies to the NSF standards. You could ingest it without any harmful effects.

More importantly, you won’t have to scrap the product produced and start all over again.”

One aspect that needs to be stated is that LP09 solid grease needs to be used with stainless-steel bearings that are also produced by the company, because the solid grease contains no rust inhibitor additives. Bearings are an important part of any manufacturing facility, including those in the food and beverage sector. NTN’s stainless-steel bearings will last up to 20 times longer than some of its competitors. And along with the LP09 grease, will do their part in making sure that a processing plant will be running at its optimum.

“It’s about peace of mind,” said Rebecchi. “This is what production and plant managers are looking for in their production processes because it not only helps guarantee their output and yield, it also leads to a reduction of rejects. From a consumer point of view, and as a manufacturer, they are making sure that they have a lot of it covered so the product comes out to the correct specification all the time. We are assisting and improving that process with this grease.”

What it also covers is compliance. This is something that is becoming prevalent as more standards and regulations are implemented. Consumers not only want to know about the calories, packaging and make-up of a product, but also where it came from and where it was processed and packaged. And under what conditions.

“The food and beverage processing industry is very highly regulated and is becoming more so,” said Rebecchi. “The world needs to be fed and there is a growing population so there is more governance within the industry where manufacturers need to be 100 per cent compliant. Plant managers will know that if they are using NSF-compliant grease from NTN then they are on their way to compliance.

“This opens up export markets. It’s also good as a corporation from a corporate social responsible point of view that you’re doing the right thing by the environment. You are eliminating waste. You’re producing to a standard to where your manufacturing processes are optimised all the time. This is what this grease allows you to do. Our bearings and LP09 solid grease are of very high quality and designed for specific solutions,” he said. “That is where our customers can get involved with our engineering and sales people for specific solutions to unique customer requirements. NTN will come up with a direct solution if possible.”