Motion Australia’s Troy Markland, Product Manager for Power Transmission (PT), Chain and Ironware understands that behind every great food production operation is a great power transmission product.

“Power transmission is huge in the food processing space because every food production plant has conveyors operating around the clock to keep up with demand,” he says. “From farm to fork, every food product goes through processing to arrive at the final product. Every single tomato will go through a series of conveyor processes before it ever sees the shelves of the store.”

Importantly, at a food production plant, a conveyor breakdown can halt production and incur loss of valuable perishable products, according to Troy.

“For this reason, it is absolutely critical for plant workers to keep up with regular wash down and maintenance cycles of the conveyors to ensure food-safe hygiene and reduce the risk of incidental contamination.”

A growing emphasis on food-safe power transmission products has given way to the rise of innovative new conveyor product designs that are geared towards the specific needs and requirements of the food processing industry.

This trend has positioned Motion Australia well in the market as a solutions-based organisation that enjoys a longstanding working relationship with one supplier of such innovative products: the global market leading brand, Regal Rexnord.

“Regal Rexnord are a well-recognised and reputable brand in the power transmission space, which is why they are the preferred brand for many OEMs,” says Matthew Byrnes, Business Development Specialist for the Food and Beverage sector at Motion Australia. “And we at Motion, are their preferred distributor.”

“Through a collaborative approach, we work together with the Regal Rexnord team to assist customers, which includes joint site calls and collaborating on application assessments,” he explains, adding that: “Working closely with our suppliers out on a customer’s site is one of the best parts of the job.”

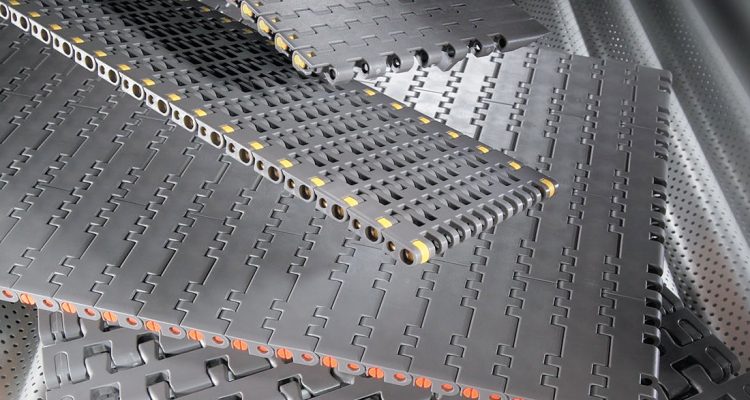

When it comes to food-safe conveyor solutions, Regal Rexnord has a diverse portfolio of Flat Top and Mat Top Chain conveyor products. And according to Matthew, these products have seen a sizeable influx in sales across the food industry in recent years.

“Industries such as dairy, flour, sugar, grains, seafood and even petfood have been converting to Regal Rexnord Flat Top Chain due to its modular assembly options and quick clean features,” explains Matthew.

“The Flat Top Chain is among the most advanced food safe conveyor belt technology on the global market right now, which in part explains the huge uptick in sales. But I would also attribute the boom to the growing interest in more food-safe hygienic products.”

The team at Motion Australia has worked with Regal Rexnord to streamline the Flat Top and Mat Top Chain range, offering start-to-finish customised conveyor designs that are fully modular and readily replaceable.

“For every food process, Regal Rexnord has an offering in this range,” says Troy. “It’s very versatile and works on an open hinge design with a smart pin retention design, which allows for a lot of flexibility when designing and constructing a conveyor line, as well as easy disassembly.”

“The chain is available in a range of materials and textures as well—acetal, polypropylene, and polyethylene—in solid, perforated or nub top designs that can accommodate different application processes, from washing, to cooking, cooling, and freezing,” he adds.

“Customers really appreciate the versatility of the Flat Top range— and being a global supplier, Regal Rexnord has excellent stock coverage,” concludes Troy. “Our close working relationships with suppliers like Regal Rexnord allow us to better assist our customers in keeping up with steadily increasing production demands.”

Regal Rexnord Flat Top and Mat Top Chain

Key Applications:

• Washing and draining

• Cutting and dicing

• Cooking

• Cooling and freezing

• Packaging and crating

Features and Benefits:

• Strong carrying surface for dynamic load handling

• Conveys larger volumes of product for increased production

• Open hinge design for fully modular construction

• Smart pin design: Easy screwdriver assembly and disassembly

• Easy access for sanitation

• Abrasion resistant

• Material Options: Acetal, polypropylene, or polyethylene

• Texture Options: Nub Top, Flat Top, or Perforated Top