In food and beverage manufacturing, filling and packaging are the final steps before the products can be finally shipped out to customers. As such, any bottlenecks in the filling or packaging process can hamper the entire plant’s operation and – in case of perishable foodstuff – send large quantities of product to waste.

Food packaging machines like bottle and jar fillers, tray packers, shrink wrappers and palletisers all have one thing in common: They all rely on rolling and linear motion bearings to carry out their repeated motions, from putting caps on bottles to folding the boxes for the final packaging.

Globally, major original equipment manufacturers implement Schaeffler rolling bearings and linear guidance systems in their food processing products. With many of these machines eventually ending up being installed in factories around Australia, Schaeffler Australia Key Account Manager, Greg Peck, says technical support for these machines falls on the Schaeffler Australia team, in collaboration with Schaeffler’s long-term bearing supply partner, Motion Asia Pacific.

“Bearings for the food and beverage industry are not that different from bearings used in other industries. Every food processing plant has pumps, motors and other rotating equipment that rely on quality bearings. Schaeffler offers a complete line of high-precision linear systems and components with corrosion protection options as well as highly effective sealing options that ensure reliable, around-the-clock operation,”

says Greg.

Apart from rolling bearings, Schaeffler also provides a complete range of linear systems that are highly customisable.

“Schaeffler’s linear systems such as four-row and six-row rail guidance systems need customised rails. Motion Asia Pacific representatives support the customers’ needs by specifying the product configuration in term of track length, preload and tolerance class. Schaeffler has state based sales engineers to support Motion Asia Pacific representatives to adapt our solutions to customers’ needs,” says Greg.

Schaeffler’s range of linear guidance systems is very comprehensive in scope and covers linear systems for a wide variety of applications. For over 70 years, the INA linear guidance systems have provided highly customised solutions to a wide range of industries.

Like most of Scheffler’s products, the INA linear guidance systems have undergone improvements over the years, with many of these components available with Schaeffler’s X-lifeTM seal of quality, which denotes ultra-high-performance products from the Schaeffler INA and FAG brands.

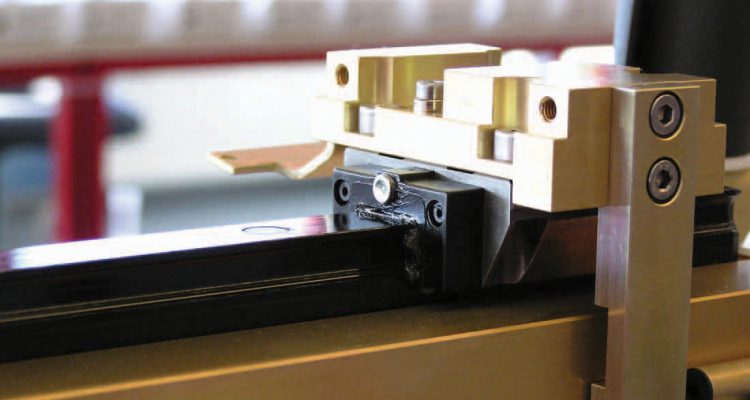

“One of the most popular products in the INA linear guidance systems is the profile rail guidance systems. These systems are available in four-row and six-row ball bearing and guideway assemblies with high load capacity and rigidity. We also offer a linear roller bearing system in this category that is suitable for very high loads and applications which require high rigidity,” says Greg.

A unique feature of the Schaeffler profile rail guidance systems, according to Greg, is the enhanced sealing options provided by Schaeffler.

“We have a range of sealing options and end pieces for the linear bearings to prevent ingress. This makes these linear systems particularly attractive options for food and beverage plants. Schaeffler is also the first company in the world to introduce optional corrosion resistant coating on all of the carriages and rails used for our linear systems. Particularly in bottling environments where you have a lot of water washdowns and spillage, this ensures bearings in linear systems remain protected,” he adds.

Apart from the profile rail guidance systems, Scheffler also provides shaft and ball bushings, track roller guidance systems and linear actuator systems in the linear range. With all of those solutions, Greg says the full technical support from Schaeffler and Motion Asia Pacific is what sets the company apart.

“The Motion Asia Pacific team are experienced when it comes to bearing solutions for the food and beverage sector. Motion Asia Pacific sales representatives and product specialists are supported by the Schaeffler engineering department and sales engineers in every state to provide truly fit-for-purpose solutions to the food and beverage sector,” he concludes.