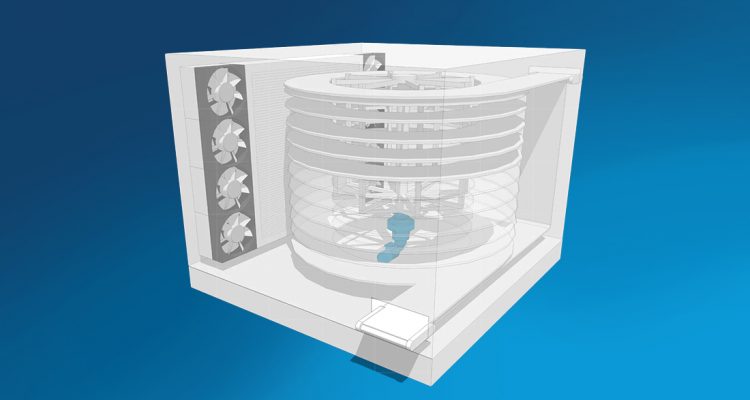

When it comes to food handling and production, time is a valuable resource. If managed poorly, it can lead to both output delays and product loss due to non-compliance with health regulations. As an answer to these concerns, many businesses have opted for spiral freezer lines, which are more efficient and compact than traditional tunnel freezers options. They operate on a spiral-shaped conveyor, driven by a centrally mounted gearmotor.

The primary benefit of spiral freezers is that they can process high volumes of material in less time, allowing a continual process free of interruption. Maintaining flavour, texture and moisture levels throughout the freezing process is paramount, which means strict atmosphere control and reliable systems are of the highest priority. Spiral freezers are an excellent option due to their minimised spatial footprint and 360-degree coverage, but they can only operate to maximum capacity when fitted with purpose-built gear systems.

Bonfiglioli’s comprehensive range of industrial-grade gear units, inverters and motors enable food manufacturers to rely on fast turnaround maximised uptime. Products including their S2U IP66, S2U, 300M, Active Cube, Agile, BE, BSR, and A Series are all capable of sustaining power in extremely low temperature settings. They are also durable against rigorous cleaning and wash down procedures necessary on food handling sites.

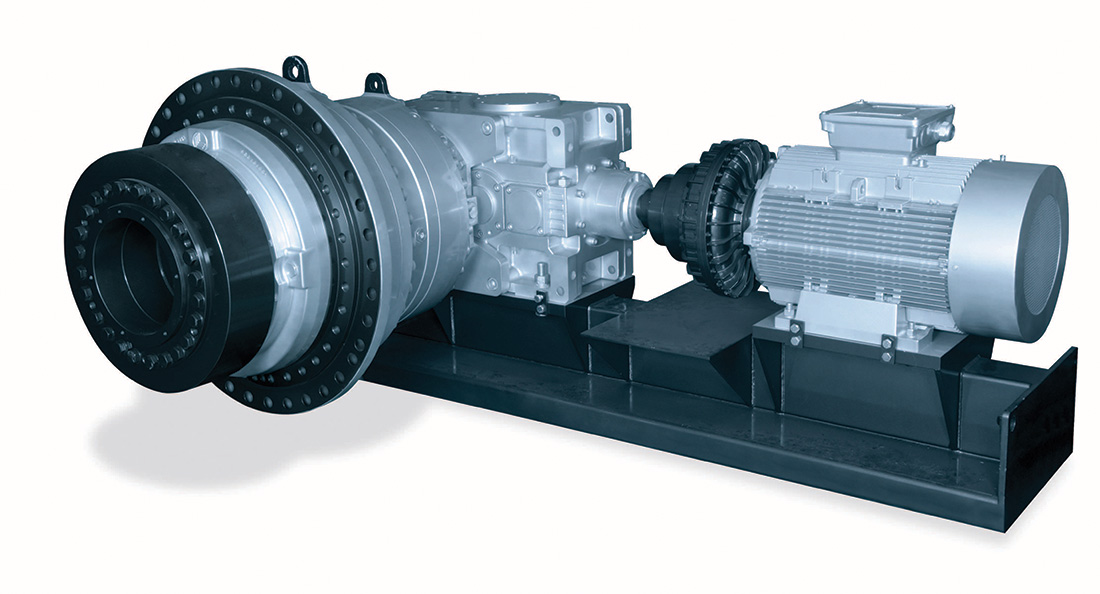

Bonfiglioli’s planetary gearboxes boast a complex design allows high shock load resistance, as well as low-temperature lubricant and oil seals. They feature anti-condensation heaters, and premium grade thermal protection (bi-metallic, PTC or KTY). This gives customers better control over their cooling systems, trusting in minimal wear and long-term product for their investment.

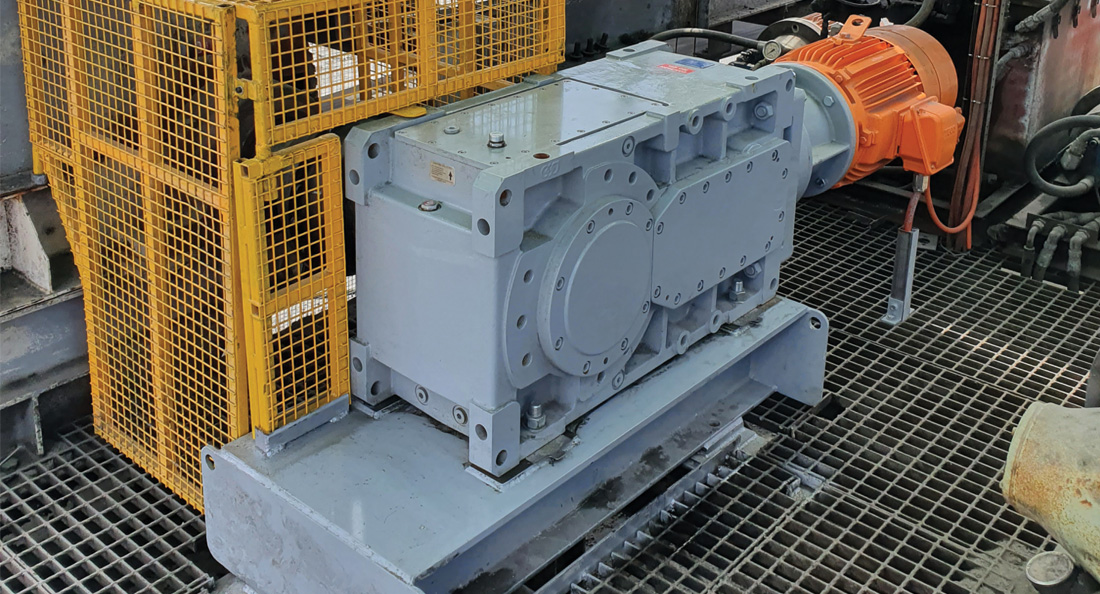

It is critical that spiral freezer components can operate reliably under pressure and where water is an ongoing presence. Bonfiglioli’s gearboxes integrate a water defender system, which ensures protection for bearings and lubrication seals against incidental splash and condensation. They have a protection rating up to IP56 and are supplemented by a total quality inspection certificate upon installation.

Spiral freezers are often running at below -40 degrees Celsius and must comply to food industry standards such as FDA and HACCP. This means that the motorisation units need to be compatible with food grade lubricants, causing minimal interference with closely controlled environmental factors such as temperature and humidity.

These rotating freezer designs can incorporate either a top or bottom drive system, depending on how it is situated in the plant. Bottom drive layouts will follow a right-angle solution with a bevel stage, whereas top mounted gearboxes typically form an in-line layout. Both will receive speciality zinc coating for protection against corrosion. To internally protect the parts, spiral freezer gearboxes are filled with oil to prevent water contamination – adjustments are often made to account for oil contraction in extremely low temperatures.

As Australia’s largest distributor of power transmission and associated technical products, Motion Australia works closely with Bonfiglioli to implement these solution-based designs across the food and beverage industry. Whether it is an urgent gearbox replacement, maintenance and repair or developing streamlined frameworks for new customers, Motion Australia’s expert team of technicians and sales representatives can provide ongoing support.

For businesses looking to achieve powerful transmission in harsh conditions – without compromising with downtime – Bonfiglioli has a comprehensive approach to addressing everyday hurdles. Their gearboxes offer the most in flexibility thanks to multiple outputs and input configurations across many different size options. The brand offers cohesion and compatibility across all componentry required to keep spiral freezers running and efficient, reducing the need for inventory clutter and overspending.