When owners of the Viva Energy Geelong Refinery planned a major maintenance programme during 2020, they had no idea COVID-19 was going to hit. The programme involved shutting down the core of the refinery for almost two months while central elements of the plant underwent a significant overhaul to prolong their operating life.

Darren Casboult, the refinery’s Central Maintenance Workshop Supervisor, says with the restrictions imposed on the site because of the pandemic and the subsequent changes to the scope of the programme, it would have been difficult to meet the tasks on time without supply partners like CBC, namely the Geelong branch.

The overhaul, estimated at over $100 million, was completed in exactly 233 days and the Viva Energy Geelong Refinery returned to full production before the end of 2020.

“If our team hadn’t been so well prepared, there is no way we could have responded the way we did when the pandemic hit and changing the event scope brought forward the start date by eight weeks. With CBC’s help in fast tracking the delivery of the components, all tasks were finished on time,” says Darren.

“CBC Geelong worked with Viva Energy in 2020 to meet our COVID-19 way of life. Viva Energy had to completely rethink the way our maintenance team would deliver the work. We had to factor in physical distancing, increased hygiene, and fewer people on site. We also had to respond to changing government regulations, which at one point involved introducing masks for everyone onsite over the space of one and a half days. CBC also made a significant contribution,” he adds.

CBC Geelong Senior Accounts Manager Brian Crouch has been regularly engaging with Viva Energy Geelong Refinery for the past 28 years. He says the CBC-Geelong team was one of the technical teams allowed on site during the months-long lockdown in Victoria.

“During the few months of strict lockdown in Victoria, we were given special clearance from the senior plant management team to continue operating on the project. Through this period, CBC Geelong was able to assist the Viva Energy maintenance teams by sourcing a full spectrum of consumable products, from fasteners to seals, bearings, belts and power transmission products,” says Brian.

But the relationship between Viva Energy and CBC is not limited to supplying parts. Brian says CBC engineers have also been able to offer design improvements to the site on multiple occasions over the past years.

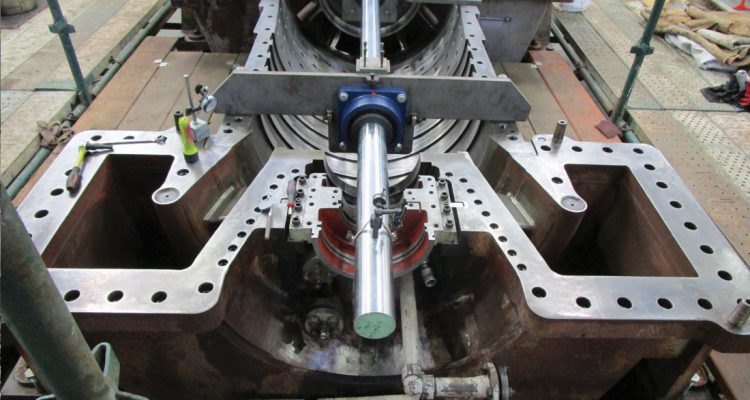

One of the latest, which took place during the recent overhaul event, was upgrading a fan blower assembly in the refinery’s steam cracker unit using the Timken spherical roller bearing solid block housed units.

“The main air blower in the cracker unit is a critical piece of equipment that is driven by the main steam turbine. The blower can operate up to 12500 kw of power under load and has an output speed of 5610 rounds per minute (RPM). This equipment is usually overhauled every 10 years and the bearings and couplings are replaced to extend the operating life.

“When setting this up in the Viva Energy workshop, we offered to replace the bearings with the Timken spherical roller bearing solid block housed units. Because of the width of the shaft and the setup of the coupling, we needed a bearing unit that was robust and strong enough to handle the application. We used the Timken spherical roller bearing solid block housed units for this purpose as they can handle extreme loads and also offer exceptional sealing properties,” says Brian.

This was not the first time Brian had offered design improvements to Viva Energy that had helped in improving equipment reliability. Another instance that stands out for him even after more than 10 years is the design and supply of a replaceable inline housing for the plant’s fin fan drives.

“One of the biggest projects I was involved with at the refinery was the complete design and supply of an inline housing back in 2009. The reliability engineers were experiencing recurring failures in an application so I and the other engineers in my group came up with a unique design for a replaceable inline housing unit that can be pulled out in situ rather than having to be moved to the workshop for repair. We also designed special bearing seals that have helped the housing unit remain in operation since 2009 without any failures,” explains Brian.

“CBC Geelong also offers 24/7 emergency service back up to Viva Energy in case there are any after hour breakdowns. We are also committed to providing training to their mechanical fitters and apprentices with our Gates belt package and bearing installation set ups.”

On a broader scale, the relationship between CBC and Viva Energy is even more deep-rooted. As part of Motion Asia Pacific Group, CBC branches work closely with Viva Energy towards distribution and after-sale support for the full range of Shell lubricants, oils and greases to all major industries in Australia.

Brian says the CBC team in Geelong is happy to have played its role in ensuring that the refinery’s overhaul was completed on time and on budget.

“We have always treated Viva Energy with a lot of integrity and respect, which has led to forging a strong relationship between the two companies. Now that the refinery overhaul is finished successfully, it’s back to normal for us, which means continuing to provide our services day in and day out at the best possible level.”