The team at CBC Dubbo isn’t just focused on delivering gearbox and motor products to end users, they are focused on delivering inventive engineering solutions, says Branch and Areas Sales Manager, Chris Anderson, who has been working with gearboxes and motors for more than 25 years.

Dubbo is a rural town with about 40,000 residents, that occupy the land between the tablelands and the mountain ranges of the Great Dividing Range. The rocky terrain makes it an ideal location for quarrying operations and positions CBC Dubbo well to serve some of the major quarries in the area.

“We have a very good relationship with the local quarries in our region who have locations for extraction of stone and rock in the area that we regularly service,” says Chris.

The quarries in New South Wales are informally regarded as historical sites having been in operation for half a century. Some of them reside as global leaders in built materials production specialising in sand, gravel and stone aggregates for the building and construction industry. Many of the materials and aggregates that these quarries produce go into the foundations of roads, schools, homes, and hospitals around Australia.

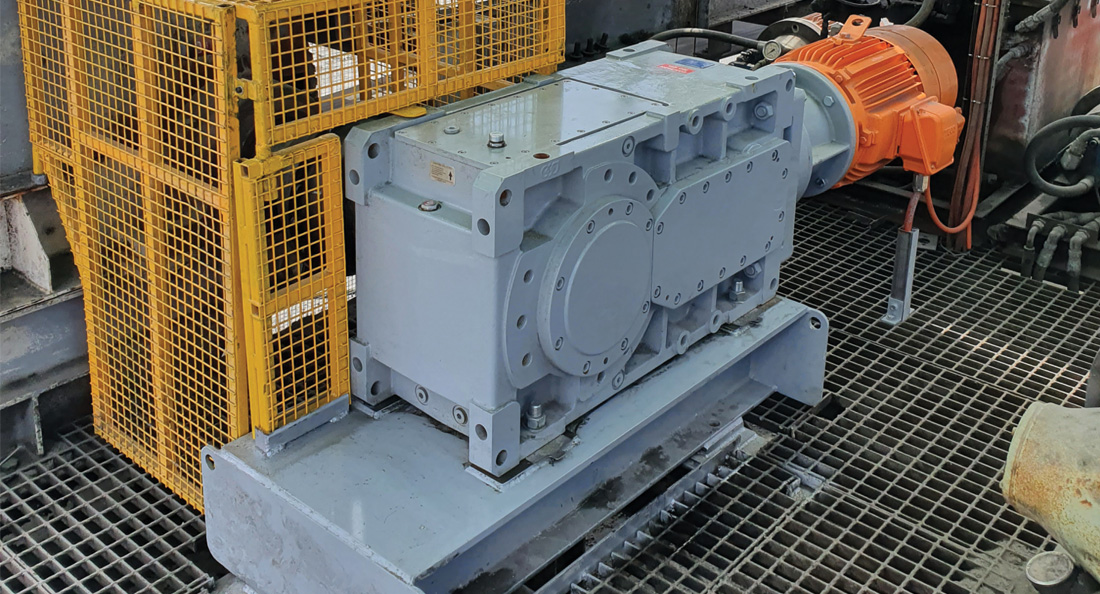

Recently one of these quarries approached the team at CBC Dubbo with a problem. Given the nature of some of the older model machines at their site, many of the gearboxes on the site were legacy models that had not been updated to align with the pace of new motor technology.

As a result, when a motor would breakdown, the quarry’s maintenance staff were forced to remove the broken motors by cutting them out, rendering head drums and rolling conveyors on site out of commission while they struggled to find a replacement for the old model motors.

Chris and his team at CBC Dubbo went out to visit the site and surveyed the gearbox and motor arrangements to see what could be done to make them more efficient and easier to maintain.

“The first thing that came to my attention was the existing shaft mount boxes were welding onto shaft, requiring works to cut off the entire shaft which was extremely costly, and time consuming. Furthermore, the old gearboxes were inefficient in terms of power, and ultimately causing a lot of downtime on their conveyors,” says Chris.

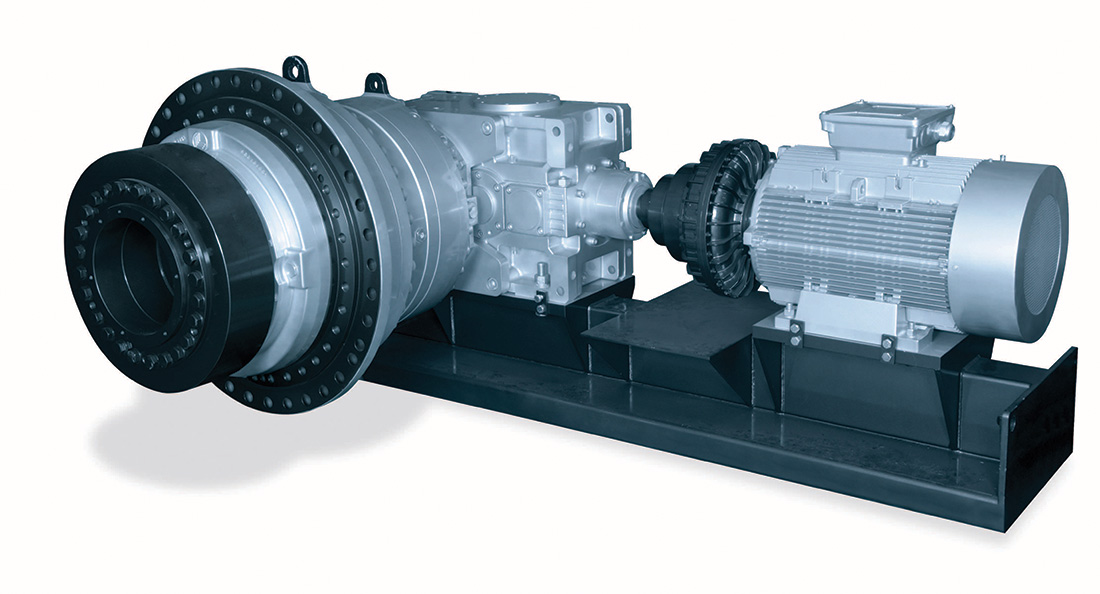

The solution Chris offered was to fit all of the head drums with Bonfiglioli Bevel Helical gearboxes, because they are modular and easy to change them out.

“We had the components readily available through Bonfiglioli and because they are modular, we were flexible on the method of installation,” explains Chris.

“The team at the quarry were very grateful for the solution — if the motor fails on their new gearbox, they now have the ability to unbolt the motor and bolt up the new motor quickly. If the gearbox itself fails, they can remove the motor and the coupling and set them aside to be re-used, and then just replace the gearbox. Easily done.”

Bonfiglioli is one of CBC’s premium partners and have been instrumental in providing exceptional service to quarrying segment, as demonstrated by another recent example Chris presents.

“Last Thursday, one of our customers had a breakdown on another gearbox elsewhere on their site, so we contacted Bonfiglioli Thursday afternoon and got approval for a new gearbox for Friday morning,” says Chris. “On Friday morning, Bonfiglioli put the gearbox together and had it ready Friday afternoon. We couriered it to the customer on Friday night, and it was installed on Saturday morning.”

All in a day’s work for the team at CBC Dubbo. “This kind of expedited service is what customers have come to expect from the team at CBC Dubbo,” concludes Chris. “And we got to see another customer walk away happy, which is what makes our job rewarding at the end of the day.”