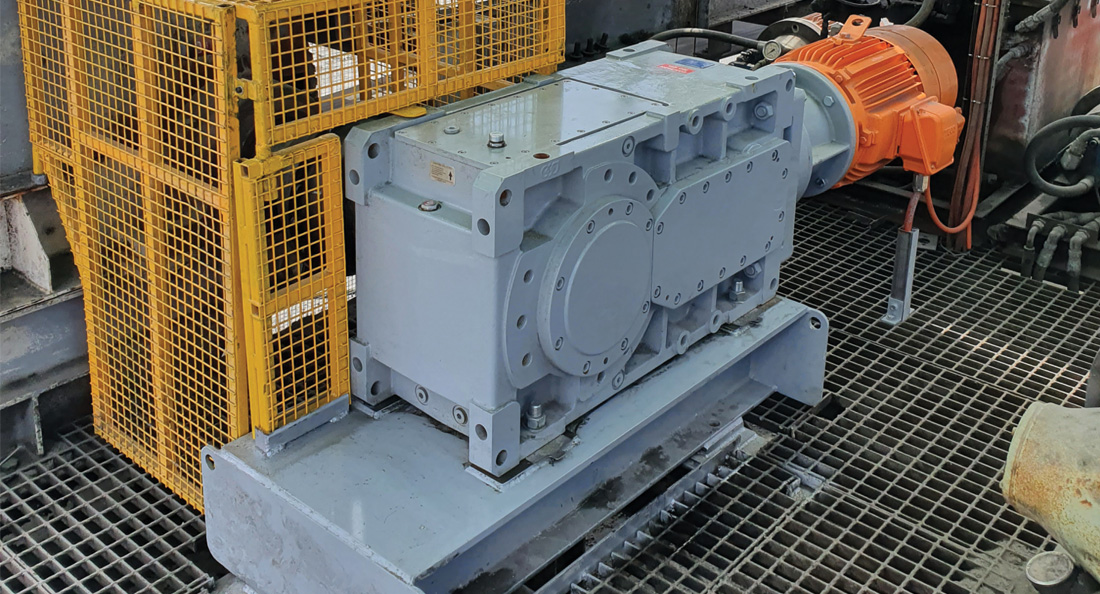

For robust, reliable, heavy duty gear units for harsh industrial environments, customers rely on Bonfiglioli to deliver solutions that are industry-specific, and tailor made to meet the requirements of heavy industrial application, across multiple sectors.

With more than 60 years of experience providing full integrated gearbox solutions to the mining, quarrying and extractive industries, Bonfiglioli’s deep understanding of application requirements —both technical and environmental— gives them an edge over competitors.

Whether it’s updating a legacy gearbox, or replacing an existing model with more advanced, IoT compatible solutions, Bonfiglioli has modular, customised solutions that allow for streamlined product selection, fast delivery, and easy installation.

Bonfiglioli’s e-business software Mosaico allows customers to select the right products to suit the requirements of their equipment, access technical data, and configure their products online.

By employing the latest in gearbox technology, lean manufacturing processes, and industry 4.0 capabilities—combined with a vast global presence that comprises of 14 manufacturing plants around the world — product excellence is Bonfiglioli’s top priority.

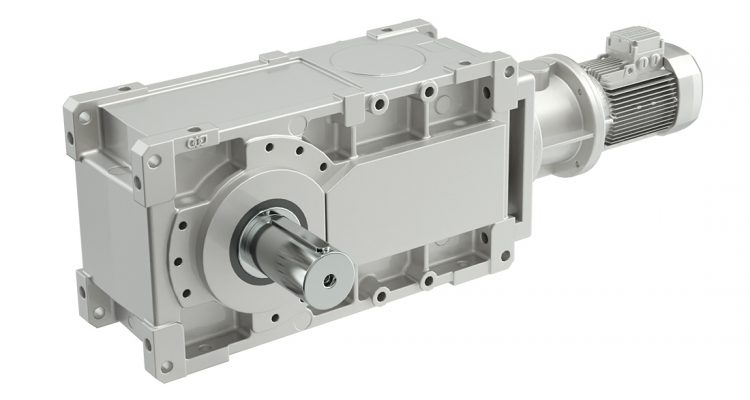

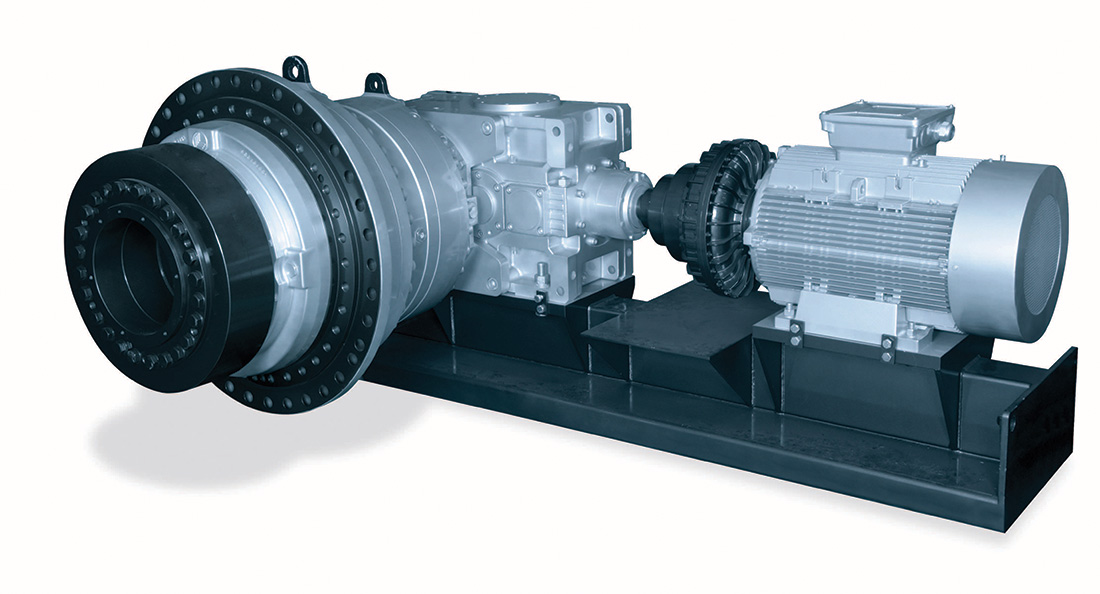

Bonfiglioli’s HDO Series Helical Bevel Heavy Duty Gear Units are exemplary of this standard of excellence.

With housings constructed of spheroidal cast-iron, high-quality shaft and gear materials matched with the latest manufacturing methods makes the HDO series drive durable and suitable for demanding applications like feeders, crushers, floatation cells. With the correct sizing and options configuration, the HDO series will be your partner in keeping equipment running and the running costs down.

As a Strategic Supplier to Motion Australia, Bonfiglioi enjoys a longstanding distribution partnership with Motion’s group of businesses. Products such as the HDO Series Helical Bevel Heavy Duty Gear Units Series range and other power transmission products are available through one of 140+ branch locations.

Bonfiglioli’s HDO Series Helical Bevel Heavy Duty Gear Units

Design Features

• Top torque density

• Silent and vibration-free operation

• Lifetime calculation in accordance with the applicable ISO and AGMA standards

• Extensive customisation options

• Highly transmissible power

• Robustness and reliability

• Mounting flexibility

• Usable in explosive environments

Main options

• Mine Spec. Fan Cooling

• Air-oil and water coolers

• Anti-Run Backs in excess of 200% rated torque

• Forced lubrication

• Temperature and oil level sensors

• Drywell

• Taconite seals

• ATEX certification for explosive environments

Motors

• Input with solid shaft

• Input with e-motor coupling:

– BN, BE, BX [IEC asynchronous]

– BSR [IEC reluctance]

Motor options

• Thermistors and thermostat sensors

• Independent forced cooling

• Incremental, sin/cos absolute single/multi-turn encoders

• Tropicalization

• Anti-condensation heaters