As industries, such as mines and quarries, move to larger pumps for more efficient dewatering, hydraulic system specialists at Dixon and CBC want to ensure their customers have access to high performing hoses, couplings and hydraulic fitting assemblies to minimise any risk of unwanted down time.

Mike Casey, Regional Sales and Business Development Manager at Dixon Asia Pacific says the dewatering market in Australia has been progressively moving to bigger pumping systems in recent years.

“Pumps with outset sizes in the three-to-four-inch diameter range have given way to 10- and 12-inch diameter pumps to help operators drain water more efficiently and in less time. Progressing to larger output units means that more water volumes need to be transported at higher pressure and it’s this pressure that ultimately dictates the grade and type of hoses, valves and couplings required,” says Mike.

Retention of the hose tail to the pump is one potential weak link as water pressures increase in the hose.

While traditionally two-bolt and four-bolt clamps have been used to tighten the hose tail, such clamping techniques can be inadequate in high-pressure flow conditions, which may lead to the hose disconnecting from the pump frequently and causing unwanted delays in operation.

This is where CBC Product Manager, Michael Rowe, says CBC and Dixon’s services really come to the forefront. Apart from being a key supplier of Dixon’s delivery hoses, fittings and valves, CBC branches across Australia work closely with Dixon to provide services such as crimping and fitting hoses with ferrules and sleeves for effective hose retention.

“Most of our customers do not have the big crimpers to cut the hose and re-fit it with ferrules or sleeves. We offer the service where they can return the hose to us and we can re-fit the assembly, pressure test it and return it to them as early as the next day, depending on where the customer is located,” he says.

As Product Manager for Fluid Transfer at Motion Asia Pacific Industrial Solutions Australia (comprising CBC, BSC and WebsterBSC sister companies), Michael says the CBC sales staff regularly consult with the sales team at Dixon to educate their customers on the best dewatering solutions applicable for their requirements.

Dixon’s Layflat delivery hoses, which are used extensively across mining, quarrying, construction and irrigation, are particularly popular for high-lift drainage of water. Ease of transport and handling makes these delivery hoses particularly popular in applications such as dewatering high sided coal mining pits.

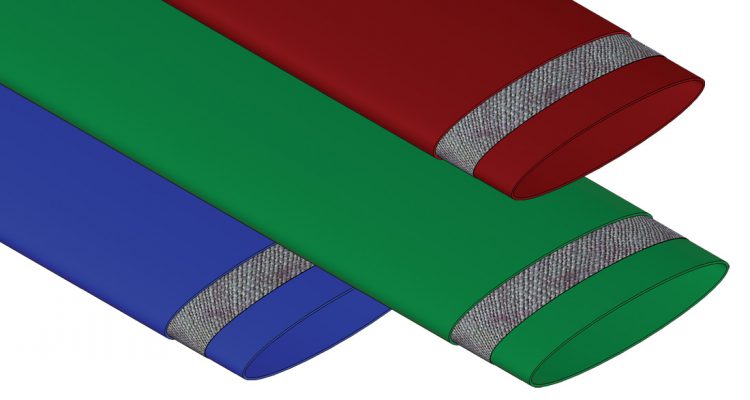

Dixon provides Layflat hoses in three performance classes, including medium duty (blue), heavy duty (red) and extra heavy duty (green). Mike says it is critical that customers choose the right hose that matches their requirements to avoid costly down times.

“If the dewatering hose bursts, it can pose all sorts of safety issues, not to mention the delays and down times in operation. While you can use joiners to repair burst out hoses, this will create issues when you roll up the hose. That’s why our recommendation to our customers is to always use the appropriate class of Layflat hose that fits their requirement,” says Mike.

As for any hydraulic assembly, the ultimate performance of the hose depends on the couplings used for their fitting. Dixon offers a wide range of couplings, each suited to a different water pressure level, as Mike explains.

“Bauer couplings have been a popular choice for end connection systems in dewatering applications for many years. That’s mainly due to ease of installation, as well as the fact that they allow for up to 30 degree bending angle. For higher pressure requirements, we often recommend solutions such as roll grooved fittings and Storz couplings to make sure the hose tail is securely fitted irrespective of water pressure,” he adds.

With many years of experience in providing hoses and fitting solutions to the Australian industrial market, Mike says Dixon regularly updates its product portfolio to align with the industry’s requirements.