Rotating Bearings tend to be the ‘star’ components of production machinery, with the importance of their role discussed often. However, industry expert John Tawadros points out that linear bearing guidance systems are just as essential, particularly in production environments where high dynamic loads and contamination can impact production efficiency.

“The linear bearing systems function in the background. Most of the time we talk about the large, robust rotary bearings that take the pounding of heavy industry, but the linear bearing technology is critical in production machinery, not only when highest accuracies are specified but also when operation takes place in hostile environments. You don’t hear much about these unique linear applications, but they’re just as important,” enthuses Tawadros, who is the National Key Account Manager for Schaeffler Australia.

And while applications within the building material manufacturing sector are diverse and wide-ranging, the commonality between them all – whether that be in the manufacturing of glass, plasterboard, bricks or timber – is that their environments are harsh on equipment.

“One of the key problems that arises is liquid and foreign particle contamination. The other is related to the types of loads experienced,” explains Tawadros. “The impact and vibration, combined with speed and harsh environments, will take its toll on any moving part in the machinery.”

Tony Tormey, CBC Australia’s Product Manager of Industrial Bearings, concurs that the most common issue among building material manufacturers is downtime due to premature failure of equipment from either contamination or the stress of heavy loads.

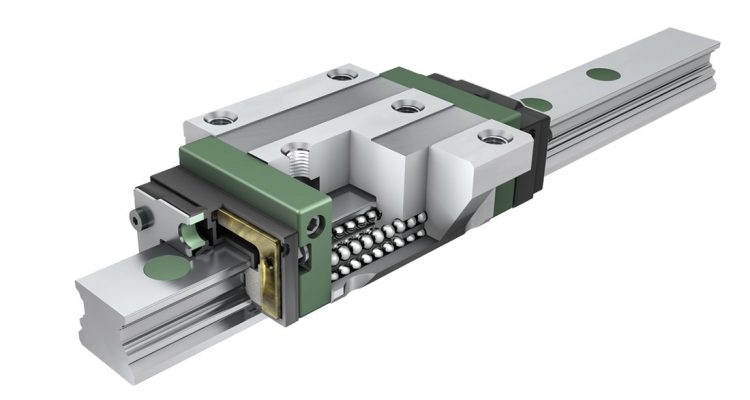

Schaeffler’s INA monorail linear guidance systems address a number of the industry challenges that Tawadros and Tormey cite above. These robust monorail guidance systems are recommended for applications that require the moving of heavy loads with precise linear travel.

“They are used where linear guidance is required as they have the ability to carry heavy loads with a high running accuracy and speeds of up to 150 metres per second,” explains Tormey. “For example, an application where these would be used is in a timber plant, where timber is being planed and the finish needs to be extremely accurate.”

According to Tawadros, the Schaeffler INA linear guidance systems in X-Life option have a market-leading load capacity.

“Schaeffler INA linear systems are high load carrying capacity systems. In particular, the RUE-E recirculating roller assemblies have the highest load capacities in their range,” he explains. “Moreover, these systems are extremely rigid, which minimises the effects of vibration and load. High rigidity also reduces bearing deflection thus offering more accurate machining results.”

The INA linear systems also have a number of features that can inhibit contamination.

“On the contamination side, the INA linear systems are available with different modular sealing kits and also include an option for relubrication systems which minimise the ingress of foreign particles and liquids,” Tawadros says. “Additionally, because these environments are so corrosive, the Schaeffler INA linear rail systems are available with surface coatings such as our trademark Corrotect® coating to provide corrosion protection.” This coating is so robust that even scratches on the coating will not corrode due to cathodic protection, making it very suitable for ‘rough’ environments.

Tawadros emphasizes that the Schaeffler INA linear systems are all bespoke. In fact, the technology was developed in response to actual customer requirements and is based on a modular concept that enables each system to be customised to match a customer’s requirements and application exactly.

“In terms of the solutions we offer, we also have a range of complete linear driven unit options. These all-in-one units are available in a number of configurations and drives in a single guidance system concept,” he says. “On top of that, we have Industry 4.0 solutions to monitor the operation of critical production machinery.”

These bespoke linear systems also come with bespoke service and technical expertise. This is why the relationship between Schaeffler and CBC is so critical.

“CBC have branches in strategic locations to service the building industry with all its Schaeffler linear requirements, including our experienced engineering teams,” stresses Tormey. “We have a long-standing relationship with Schaeffler and work very closely together to maintain uptime within this industrial sector.”

Tawadros highlights the fact that Schaeffler and CBC have been “partners in industry” for over 60 years.

“Schaeffler greatly values the relationship that has developed with our distribution partner CBC. CBC’s experienced and dedicated team backed up by Schaeffler’s R&D technology and manufacturing know-how offer a unique and wide-reaching service to our clients. Together, we share a passion for creating solutions for industry.”