While infrared thermography is predominately used as a form of condition monitoring on electrical and mechanical systems, it can also be used to identify safety hazards.

This specialised service – thermographic analysis – is especially useful for manufacturers of building materials, particularly producers of cement, glass, timber and plasterboard, to ensure onsite machinery is performing within safe and efficient parameters.

Steve Blott of FLIR Systems Australia explains that downtime for manufacturers in the building material manufacturing industry can be mitigated through effective and timely use of thermal imaging cameras by trained professionals.

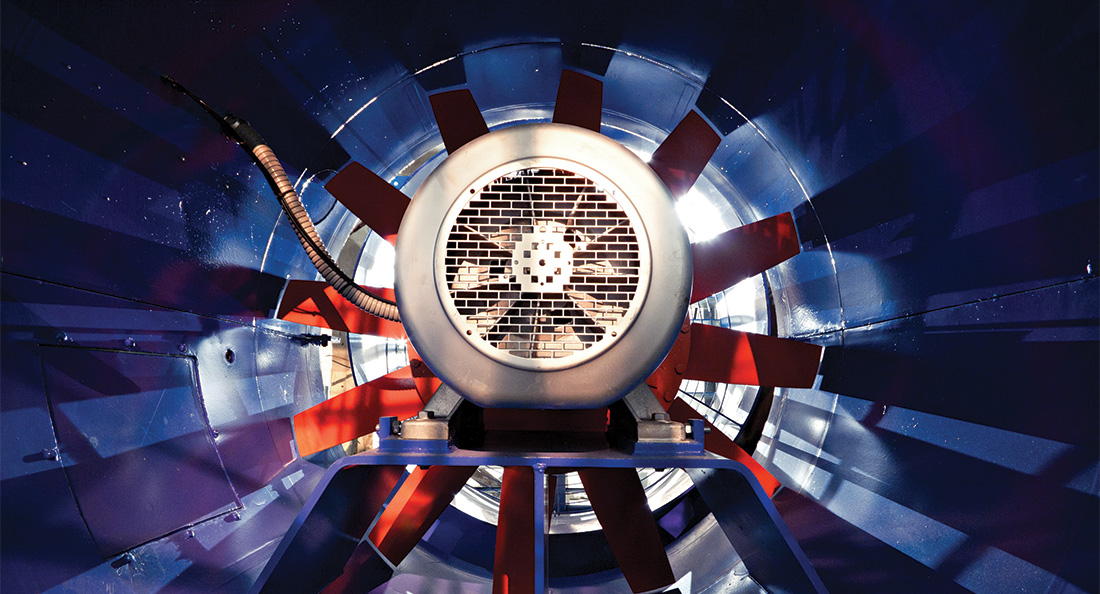

The thermal imaging camera works by interpreting radiated energy coming into the camera, which forms an image that shows the temperatures as colours. Hotter sections of the image will appear red or white whereas the colder a section is, the darker the image will be (dark blue, verging into black).

This technology is used in condition monitoring because it allows the user to see small surface temperature differences and measure any part of the infrared image to find the actual temperature on the image. Anomalies in temperature are often an indicator that something is wrong with the equipment.

Bearing failure is one of the most common causes of mechanical machinery malfunction as a result of metal-on-metal friction causing componentry to overheat. Thermographers using thermal imaging cameras are able to trend and predict equipment failure or in extreme cases identify immediate anomalies based on extreme differences in surface temperature.

“Cement manufacturers, for instance, can experience ingress protection issues with their onsite machinery when there is a build-up of dust or cementitious by-product which can lead to machines generating more heat than usual due to impaired ventilation. The use of thermal imaging cameras as part of a thermographic analysis will highlight discrepancies in surface temperatures. Armed with this knowledge, manufacturers and teams tasked with quality assurance are able to action predictive maintenance plans and pre-empt serious issues before they impact production.”

In addition to mechanical machinery application, these cameras can also be used to find overheating electrical wiring faults due to resistance issues as well as blockages in hydraulic cabling.

Meanwhile, Anthony O’Keefe, Engineering Manager for BSC, says the FLIR thermal imaging cameras that the company distributes – and actively uses among its team of specialised personnel – are not only critical to the success of the company’s thermographic operations, but also bolsters its value proposition. Therefore, positioning BSC as a market leader with access to world-leading and reliable thermographer technology.

“BSC has upskilled its service technicians to perform thermographic analyses on mechanical equipment to support clients across a broad range of industries,” Anthony says. “The work orders that BSC’s thermographic analysis team typically perform include preventative maintenance on factory equipment as well as routine condition monitoring for fire insurance reporting purposes. Ultimately, our technical support team prioritise the reliable and safe performance of rotable appliances, and we attribute much of our success and diligence for high quality outcomes to the partnership we have with FLIR.”

O’Keefe explains that while many BSC customers opt to perform their own thermographic analyses and condition monitoring, his technical teams are often required to provide training as to how to properly use the FLIR thermal imaging cameras. “On the other hand, we have a lot of customers who prefer us to come to the site and perform inspections or provide an ongoing condition monitoring service to them. Either way, because we are using the product ourselves in our services, we have the expertise and experience to guide and advise customers.”