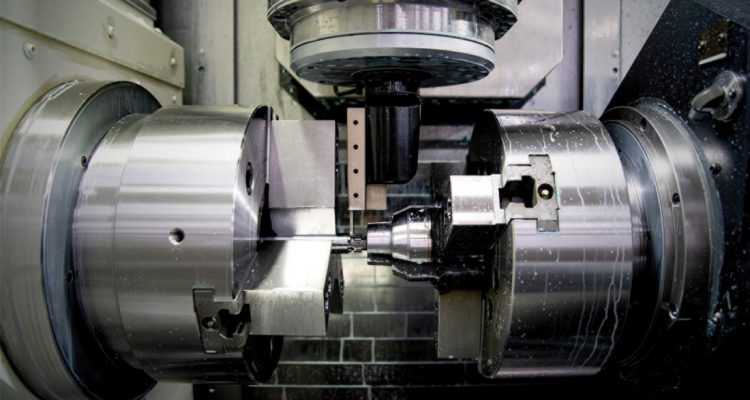

Omega Technical Engineering offers a one stop solution, with extensive experience providing a full spectrum of services from design, prototyping and production through to turnkey projects. Machining quality precision parts to exacting designs is what the Wodonga-based business prides itself on.

Omega uses advanced CNC equipment to provide sub-contracting services; and manufactures after-market performance engine accessories, for both the domestic and international markets, through their sister company Ross Performance Parts.

Established in 2004, Omega has grown from a small workshop with a single employee and two CNC machines, into a large facility with 14 full time staff and a unique combination of 13 CNC machines.

Emma Forbes is the Finance Manager at Omega and their mainline for commercial support. She explains how Omega has grown as a subcontracting business.

“We have completed sub-contracting work in a variety of industries, including agriculture, food processing, mining, and hydraulics/pneumatics. We have the capabilities to manufacture to customer drawings, or undertake a design discussion, create manufacture drawings then manufacture the parts on our CNC equipment.”

“In 2013, we purchased a Sydney based company we had been undertaking subcontracting work for a period of time. This was Ross Performance Parts and that gave us a proprietary product range,” says Emma.

Both businesses share a location in Wodonga which is situated on the Murray River on the border of New South Wales and Victoria. Strategically located between Sydney and Melbourne is an ideal hub for the industry.

Not far down the road, is the Wodonga CBC branch, where Chris Lindner has been a Sales Representative for more than 18 years. He reflects positively on his relationship with Omega that goes back for several years. Emma manages all the ordering and following up for purchase orders, so she regularly deals with the Wodonga branch.

“I talk to Emma regularly. She primarily orders O-rings and sealing products from our Seal Innovations product range. Omega is a very multi-faceted business. The O-rings they order from us are static or rotary sealing item that go into the equipment they manufacture. They have been a loyal customer for a long time and in turn we try to give back as much as we can,” says Chris.

Seal Innovations, part of Industrial Solutions Australia’s group of businesses, offers a wide range of O-rings, O-ring cords and O-ring kits to different industries. Being a sister company to CBC means CBC customers have easy access to a wide range of sealing and gasketing products from Seal Innovations.

An O-ring may be a humble dollar value item, but it is an extremely critical component of our high-performance harmonic dampers.

“We use O-rings in the manufacture and assembly of our harmonic dampers. A harmonic damper is used in a car engine for protecting the performance and longevity of the engine. Its main job is to absorb the torsional vibrations of the engine. Our particular design uses a natural rubber bonding process and a combination of one or multiple O-rings to allow the absorption of vibrations,” explains Emma.

“An engine can get vibrations at different rev ranges that can cause destruction to the engine if it doesn’t have the ability to absorb and dissipate the vibrations,”

she adds.

The relationship between CBC and Omega has remained strong over the years. As Emma points out, CBC’s role extends beyond just being a supply partner to being an advisor on specific components and parts.

“We have our standard range of products we require from CBC. But if we are doing tech development and R&D, or if we have subcontracting project that requires specific hardware, then we consult with Chris Lindner to work out the appropriate item for a particular application.”