Late last year, Regal announced a transformational merger with Rexnord’s Process and Motion Control Solutions business. According to Shane Rock, General Manager – Oceania Region for the Regal Rexnord Corporation, it was shared business values and complementary strengths that led Regal Beloit Corporation and Rexnord Process and Motion Control (PMC) to complete their merger after eight months of diligent planning.

“The recent establishment of Regal Rexnord Corporation as a wholly owned single business signified for us the coming together of a combined 125 years of engineering expertise in the manufacture of electric motors, power generation and power transmission products,” says Shane.

“The merger presented itself as a great opportunity to grow the value of both businesses and expand our product range to include a full range of motion control solutions.”

Historically, Rexnord has specialised in the design and manufacture of premium power transmission (mechanical) products, while Regal were well established as global motor (electrical) manufacturing experts.

The new company is comprised of four business segments including what are now known respectively as Motion Control Solutions, Climate Solutions, Commercial Systems, and Industrial Systems.

According to Shane, these new divisions will better enable the company to deliver more complete solutions to serve customers across the entire industrial powertrain.

Regal Rexnord’s new portfolio will be inclusive of some of both companies’ most highly regarded names such as Regal’s Browning®, Grove Gear®, Hub City®, Jaure®, Kop-Flex®, McGill®, ModSort®, Sealmaster® and System Plast® brands, as well as PMC’s Berg®, Cambridge®, CENTA®, Falk®, Rexnord®, and Stearns® brands.

“We now have unmatched engineering capabilities to deliver solutions that range from HVAC and conveying systems, to agricultural and food processing equipment, to mining and manufacturing operations,” says Shane.

“We will also have the ability to provide digital and internet of things (IoT) tchnology through the combined hardware, software and ‘humanware’ capabilities of Regal’s Perceptiv™ and Rexnord’s DiRXN® digital platforms.”

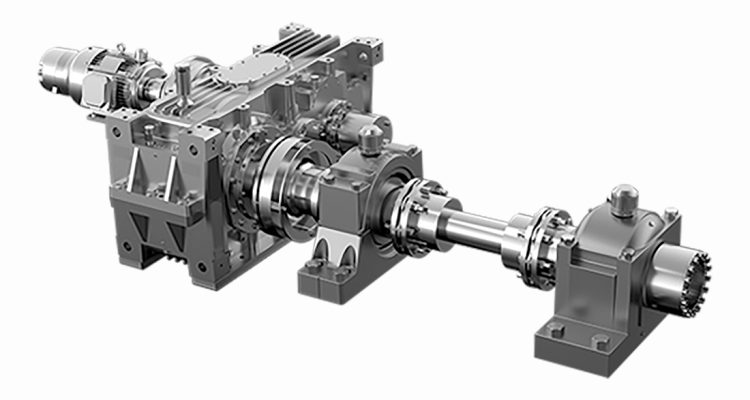

Another example of the combined efforts and capabilities of the two companies is the engineered-to-order Regal Rexnord Powertrain. Brand new to market, the Powertrain is an end-to-end optimised electromechanical unit designed to be applied to a wide range of applications and industries.

“The Regal Rexnord Powertrain harnesses Rexnord’s mechanical engineering ingenuity with Regal’s integrated IoT condition monitoring and diagnostics technology through Regal’s Perceptiv™,” says Greg Josephson, Regal Rexnord Sales and Distribution Manager. “The result is the new generation of fully digitalised powertrains that reduce the complexities of traditional servicing requirements and operational challenges.”

In addition to opening new engineering opportunities, Greg says that the merger has created boundless opportunities for improving the sales and support side of the business – facilitating the channels that will get these products out to site sooner.

“As a global leader in industrial manufacturing, the markets that we serve have remained much the same since the merger,” he explains. “But it is our goal to broaden the scope of our involvement with attractive high-growth end markets such as renewable energy, aerospace and e-commerce.”

“With this new merger, we now have the ability to offer customers a much broader range of products and we have been able to incraese our efforts toward making these products more accessible and consolidated in the Asia Pacific region.”

As the Sales and Distribution Manager, Greg’s role is to build a bridge between Regal Rexnord’s internal expertise and industry leading product experts, such as the team at Motion Australia.

“As a strategic supply partner to Motion Australia, the work we do together has been critical to streamlining our domestic operations,” says Greg. “They have been instrumental in helping drive our knowledge and capabilities across the country, as well as champion our stock availability– making possible a streamlined delivery to the doorsteps of our customers.”

National Category Manager for Mechanical Drive Systems and Final Drives at Motion Australia, Steve Hittmann, notes that for the team at Motion, the merger between Regal and Rexnord has equated to an expansion in both companies’ sales and engineering capabilities.

“The merger and expansion of Regal Rexnord in Australia has allowed us to better serve our customers,” says Steve. “Instead of needing to liaise with suppliers overseas to procure the necessary electromechanical components, we can eliminate the logistics and long lead times by leveraging Regal Rexnord’s expanded product range and stock volumes, alongside our vast network of sales and distribution centres around the country.”

In addition to having more products on offer for customers to trial and test, the team at Motion Australia has been motivated to get out to site more often on joint calls with Regal Rexnord engineers, so they can tackle more complex engineering challenges within the industries that they serve, explains Steve.

“Not only has Regal Rexnord become a single-solution supplier for a wider variety of industrial applications, but there is also ample engineering support that is presently working on the ground to assist us with customising and adapting these solutions in accordance with what our customers need,” he says.

“All around this has been a very positive move for everyone involved as together we are able to focus on delivering leading-edge technologies to customers across Australian industry.”

The Regal Rexnord Powertrain

The new Regal Rexnord Powertrain is an end-to-end electromechanical unit with boundless potential applications– enhanced in its performance through internet of things (IoT) monitoring via the Regal Rexnord Perceptiv™ intelligence platform.

Features and Benefits

• Maximises uptime and reduces energy consumption

• Works efficiently as it is engineered to optimise performance

• Reduces complexities in certification and operation

• Integrates ongoing support, services, and diagnostics from one supplier

• Well suited to bulk and unit materials handling, metals, pulp and paper, mining, and other critical industrial applications