In the fast-paced, demanding world of industrial manufacturing, power transmission is what powers nearly every process, and for more than century, Gates Corporation has been revolutionising industrial processing power by pushing the boundaries of materials science.

Over the years, Gates engineers have developed some of the most advanced power transmission solutions available to the market.

As a premium supplier to Motion Australia, Gates’ extensive portfolio of belt solutions has propelled the growth of some of the world’s most successful process businesses, solving countless problems for customers, and exceeding expectations every step of the way. Gates’ belt solutions are versatile to the needs of every industry and support every facet of an industrial operation. Wherever there are freshly harvested goods being processed, automotive parts being manufactured, water being flowing in a hydraulic pump, minerals being transported, or newspapers being printed – there is a good chance you will find a Gates belt nearby.

A Short Guide to Gates Belts

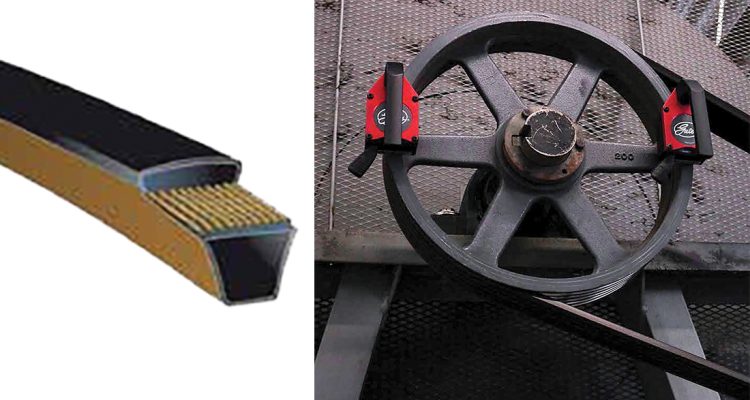

• V-Belts

Gates V-belts are engineered to run maintenance-free to keep your equipment moving without the need for lubrication or re-tensioning. Designed for wear, corrosion, and heat resistance with OE quality fit and construction for reliable, long-lasting performance.

• Synchronous Belts

From aligning engine components to transferring power between critical systems, Gates synchronous timing belts are designed to operate at higher temperatures, higher speeds, and over longer distances. Gates synchronous belts ensure light, quiet, and efficient operations and have excellent resistance to corrosion, stretch, and wear.

• Speciality Belts

Covering everything from lawn mowers and snowblowers, to truck refrigeration units, Gates innovative belts keep equipment running longer so businesses can focus on what really matters – getting the job done.

The legacy of Gates’ belts began in 1917, when John Gates engineered the world’s first rubber V-Belt, which substituted formerly ‘manual’ jobs for machine driven industrial processes – changing the face of manufacturing forever. In 1945, Gates invented the first toothed timing belt, now known as the synchronous belt, and this was followed in 1979 with the introduction of the serpentine belt that pioneered a new era for power transmission.

The Gates’ legacy doesn’t rest on a rich and storied history of innovation alone. The Gates name has been preserved by a continuous need to outperform themselves, earning the trust of customers, new and old, time and time again. But serving the needs of an ever-changing world means staying ahead of the curve. By investing in the research and development of materials science and the design and manufacture of power transmission products; and drawing on the real-world experiences of people; Gates aims to solve the diverse challenges of today’s industry while anticipating the challenges of the future.

Eddie the Engineer Recommends: Gates Specialty High-Performance Belts

• Gates® Predator® V-Belts – High powered motors. Shock loads from sudden starts and stops. Dirty operating environments. High heat. Contamination from oil or solvents. Predator® V-belts handle them all.

• Gates® PowerGrip® GT4 – Fiberglass cords, inflammable, maintenance-free, recommended for high-capacity applications requiring more strength and power than a standard V-belt.

• Gates® Poly Chain® GT® Carbon™ – Switch out chain for this polyurethane belt alternative to traditional roller chain, reinforced with carbon fibre tension cords. No lubrication required, zero re-tensioning, and 400 percent greater capacity than roller chain.