In the waste and recycling management sectors, machines and equipment are frequently put under heavy weight constraints. The repetitive nature of waste and recycling disposal can lead to failure in machinery when inadequate tools are used to maintain equipment. Baling presses are dedicated waste management machines that compress recyclable materials like paper, cardboard and plastics, into compact bundles. These machines come in either hydraulic or pneumatic compositions, with both needing robust assembly to maintain their long-term use.

Troy Markland, Motion’s Product Manager for Drive Systems and Power Transmission, says the future of manufacturing is soaring to new heights.

“Technological advancements in the industrial landscape have come ahead in leaps and bounds,” says Troy. “More and more, factories are looking to increase the rate of their productivity through high-speed applications.”

For industry workers in waste and recycling management, seeing long-term results from their machines can be achieved using robust, industry engineered couplings. Fenner, a leading name in power transmission, has been providing industrious solutions in engineering drive systems for more than 150 years. The company demonstrates an understanding of these needs through its range of couplings, dedicated in providing individual and business solutions.

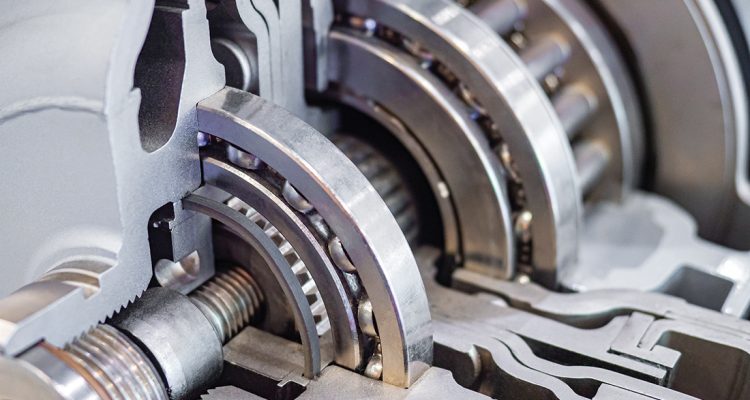

Fenner supplies four different types of couplings, Fenaflex couplings, jaw couplings, rigid coupling and HRC couplings. Fenaflex tyre couplings provide an excellent solution in preserving the structural integrity of a Baling Press.

“The Fenaflex tyre couplings are unique in their design because they have a doughnut-style rubber tyre between the two flanges of the coupling arrangement that has vibration dampening properties and torquing ability that allow for shaft misalignment on operations,” Troy says.

Heavy vibrations occur during the compacting phase in a baling press, meaning cracks and fractures can occur, which can lead to equipment failures.

“The Fenaflex Tyre Couplings do a good job of softening the impact of heavy manufacturing through shock absorption,” Troy says.

The couplings can accommodate up to a 4-degree misalignment on an application, which is above a standard coupling. However, careful calculation of the gap between the shafts and any end-float is required in ensuring the flanges are parallel with the shafts.

“The most common cause of a coupling failure is improper installation,” says Troy. “There are times when maintenance and repair staff have not received proper training on how to install the couplings, or the instructions are overlooked. The result is that a coupling will be implemented on a high-speed, high-impact, application incorrectly, which can cause cracks, fractures or breakdowns.”

Fenner provides knowledge and training hubs online to ensure users can successfully administer and use their coupling range appropriately for desired outcomes.

“Fenner produces a lot of instructional videos and training resources,” Troy says. “My advice to operational managers would be to train up staff properly and ensure they have access to these channels. Alternatively, our team at Motion is always happy to make a site visit to assess the requirements for a drive system and assist in the installation process.”

Troy emphasises the importance on performing test runs after installation and says monitoring the performance will ensure the torque is correct for the application.

“End-users will get the best results from Fenaflex Couplings if care is taken on installation,” he says. “It is important to keep installation resources close, make sure the Fenaflex tyre is seated correctly, check the gap, check the torque, and adjust the screws accordingly.”