During harvest season farmers across Australia reap what they have sown during planting season in the form of fresh produce. This raw product is transported to Food and Beverage manufacturing plants around Australia for processing into consumer products – from staples such as bread, milk and butter to snack foods such as potato chips, orange juice and soft drink.

For rapid processing of these products, reliable chain and component solutions are required to turn fresh ingredients into fast moving consumer goods that need to be packaged and handled efficiently on high speed conveyor lines, before shipping to markets nationwide.

Matt Crehan is the National Product Manager for Rexnord Australia and highlights how Rexnord has addressed the Food and Beverage industry’s increased need for speedy and sustainable solutions over the years.

“Rexnord first developed LF (Low Friction) conveyor chain material in the 1970s to address high speed conveying demands. Flash forward to the 1990s, line speeds had almost doubled, and they introduced the HP™ (High Performance) material into their range,” says Matt.

“Rexnord FlatTop has continuously developed innovative conveyor chain and component solutions to meet the increasing performance demands of high-speed filling lines in the food and beverage industries,” he emphasises.

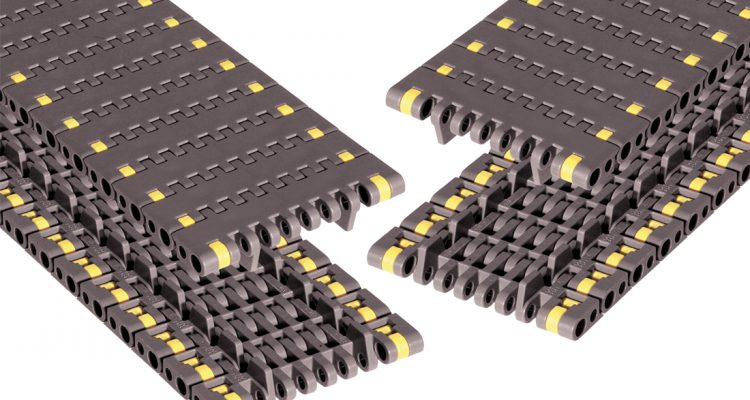

The Rexnord Platinum Series X (PSX) chain is constructed from Rexnord’s new innovative PSX® material.

“Over time, conveyor speeds have continued to increase with concerns in sustainability targeting improved safety, productivity, water consumption and reduction and energy savings. The PSX material addresses these needs and will help to set a sustainable conveyor standard for the future,” Matt enthuses.

In addition to this, Rexnord has performed extensive research into addressing the market need to convey polyethylene terephthalate (PET) containers at high speed without any external lubrication.

“With the new Rexnord DRY-PT™ Material we hope to set a sustainable conveyor standard for the future. The DRY-PT Material has proven to be the first plastic chain material to provide the lowest friction versus PET at a constant level over time, where other plastic chain materials have shown permanent increases in friction after hours of running,” explains Matt.

CBC is proud to partner with Rexnord to introduce these new PSX chain material solutions to the Australian market.

“Everyone wants to run things harder and faster these days, so your standard product is going to run out more quickly and need to be replaced,” says Troy Markland, Product Manager at CBC. “The Rexnord PSX range is a low-friction, high-performance range of product which allows the application to run faster and last longer.”

Troy elaborates of the PSX range, “The PSX TableTop range are the most versatile for applications. The TableTop 820 series and the 879 series are both very popular. The MatTop and Magnet Flex solutions are more specialised in their use applications. With the PSX range we are seeing cost savings and reduced downtime because customers are not being required to replace their chain anywhere near as often.”

The speed of the chain component of a conveyor application is directly correlated with the speed at which a product can reach the shelves. This is why CBC is encouraging operators and managers to upgrade their chain to the latest innovative material solutions that Rexnord is offering for their next harvest season.

Rexnord DRY-PT Material Run Dry Chain Solution

• High strength

• Consistent low friction

• Minimal dusting

• Long wear life

• Bright lime-green colour has been selected to make the need for cleaning visible

• Low-Friction against PET

• Material designed specifically for conveying of PET containers without need for external lubrication

• TableTop and MatTop Executions

• DRY-PT is available for all common chain series used for high-speed PET conveying

Rexnord PSX Series Chains: Platinum Series X (PSX) Material

• High strength

• Consistent low-friction

• Minimal dusting

• Long wear life

• Low Coefficient of Friction (COF)

• PSX material offers consistent low COF with aluminum and steel cans, glass and PET bottles PSX material offers consistent low COF with various wearstrip and corner materials

• Minimises Dust

• Reduces dust which is common in dry running applications

• TableTop and MatTop Variations