With populations growing rapidly around the globe and factories producing at higher levels than imaginable some decades ago, the risk of food contamination across those factories is higher than before. The machinery at the heart of those operations requires premium components that can ensure the highest level of hygiene in production.

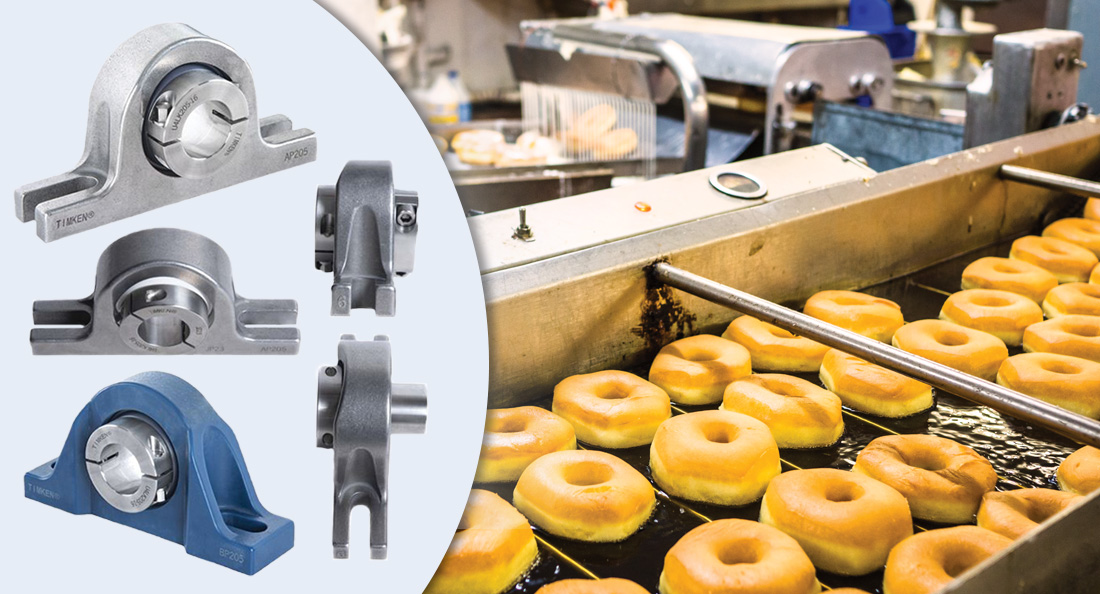

For the past few years, Timken® has been working on a new range of bearing units for the food and beverage industry. Though Timken is relatively new to the food and beverage market segment, its solutions are already finding global acceptance in original equipment.

With the next harvest season on the horizon in Australia, Motion Asia Pacific’s businesses – namely CBC, BSC and Webster BSC – across the country are stocking up with the new Timken bearing solutions for the Australian food and beverage industry.

“It’s an exciting time for both Timken and Motion Asia Pacific,” says Alf Mangano, Timken’s Regional Sales Manager for the Victoria, Northern Territory and South Australian regions. “We have partnered with Motion Asia Pacific on our food

and beverage package. Australia is

taking the lead on these products, and we want to help get the right products

to the right markets.”

Alf has been a part of Timken Australia for more than 23 years, specialising in bearings for the food and beverage industry. He also looks after original equipment manufacturers (OEMs) for his sector of the bearings market.

“Timken’s food and beverage housed units are designed to be dimensionally interchangeable with industry standards. That means if a customer has a bearing product in their production line that is not food grade, they can switch them out. These units are fully assembled and only need to be mounted. This is a huge advantage for a plant that may be operating seven days a week, 24 hours a day,” explains Alf.

Stock has arrived, three brand new food-grade products by Timken: The Blue Polymer Hygienic Ball Bearing Housed Units “optically detectable”, the White Polymer Corrosion-Resistant Ball Bearing Housed Units, and the Corrosion-Resistant Deep Groove Ball Bearings. All units are NSF H1 and FDA compliant. These are readily available from your local BSC, CBC, and Webster BSC branch.

Timken also offer solutions in the ball housed units with a stainless-steel option and a Poly-Round® option which is maintenance free. These units are particularly focused for aggressive washdown areas. The Poly-Round® units are 100% greaseless and corrosion resistant with excellent chemical resistance, washdown and able to operate in submerged application. They are capable of operating in temperatures up to 260 degrees.

The Timken goal is to reduce maintenance, elevate food safety, improve production time and extend bearing life.

Fit for Purpose

The different units have been designed to meet different requirements of the food and beverage industry. Tony Tormey, Product Manager for Industrial Bearings at Industrial Solutions Australia, part of Motion Asia Pacific offers some insight.

Blue Polymer Hygienic Ball Bearing Housed Units

“These hygienic housed units are constructed from corrosion-resistant materials, which are optically detectable, they are also NSF H1, and FDA complaint. Food-grade Solid Lube is available in NSF H1 says Tony. Timken also offer a hygienic stainless-steel model.”

“The food-grade Solid Lube is a lifetime lubrication solution that can withstand aggressive washdowns and contaminants and are maintenance free. They are available in a hygienic blue thermoset and stainless-steel housing, they’re also available in all mounting styles. The hygienic thermoset housings are cast to eliminate voids and increase strength,” explains Tony.

The Blue Polymer Hygienic Ball Bearing Housed Units are ideal for food and beverage processes in all applications.

White Polymer Corrosion-Resistant Ball Bearing Housed Units

“The white polymer bearing units have been designed with corrosion-resistant materials and food-grade lubricant NSF H1 and are FDA compliant,” says Tony.

“This is a premium bearing unit designed for all stages of production to enhance reliability and extend bearing life. We also have a stainless-steel model available in all mounting styles.”

“The corrosion-resistance feature helps to extend the life of the bearing and reduce maintenance. The ball bearing insert construction is all stainless steel including the set screw locking, and cage with a double lip seal for greater ingress protection.”

The white polymer units are a good solution for all applications.

Corrosion-Resistant Deep Groove Ball Bearings Solutions

“The Timken Corrosion-Resistant Deep Groove Ball bearings have been constructed with stainless-steel rings, balls and cages. These corrosion-resistant materials working in tandem with food-grade lubricant NSF H1 and are FDA compliant, which increases the safety of production by improving your reliability,” Tony explains.

“These units are available in standard, thin-section, narrow and miniature configurations of the 6000, 6200, 6300, 600, 618 and 619 series. They are currently available in double contact seals, as well as the option for open and double shields should they be required.”

The Corrosion-Resistant Deep Groove Ball Bearings are ideal for harsh environments and a wide range of operating temperatures, suitable for all applications in the food and beverage industry.

Poly-Round Bearing Solutions

Timken Poly-Round® is a solution product perfect for applications such as fryers, ovens, freezer tunnels, potato peelers and many other applications.

“These are solution-based products which we can source quickly on demand,” explains Tony.

“This product is ideal for extreme environment applications such as fryers and ovens, where a customer may not be getting performance out of their original bearing product. The idea will be to offer an upgrade to their current bearing. The main benefit of the Poly-Round® solution is to extend bearing life, improve uptime and reduce maintenance cost. That means improved food safety and greater production,” says Tony.

The Timken Poly-Round® bearings stand out because they are 100% corrosion-resistant and greaseless. They are constructed with lubricity in their polymer composition. This allows the bearings to operate without the need for grease and eliminates the need for seals or shields. The Poly Round bearings excel in the harshest conditions, extreme temperatures, abrasives, incomplete rotations – all while meeting stringent food safety requirements.

“When manufacturing fryers, one of the biggest challenges is finding bearings that are suited to direct food contact and submergence in high temperature oils,” says Tony.

“Timken has engineered housed bearing fryer solutions to excel in these conditions with their FA and FE Poly-Round® Housed units. Being corrosion-resistant, these are maintenance free, lubrication free, polymer housed bearing that have been designed for fryer applications,” Tony explains.

Alf concludes on Timken’s part, “This launch is a slow burn. Right now, we are launching some of our most popular food and beverage products of interest to the food and beverage industry. That will serve as an appetiser for what more

is to come.”

Timken Food and Beverage Belts

Motion Asia Pacific will also be stocking Flour Power Roller Mill and Feather Picker v-belts for specific food and beverage applications.

“The Flour Power Roller Mill belts are built from strong, smooth, high-performance polymer and are jump resistant. While the Feather Picker v-belts are double cogged with extra grip power and high-heat resistance. Both belts are durable to the demanding conditions of an industrial food and beverage environment,” says Alf Mangano from Timken.

Timken Diamond Chains

A few of the other recommended food-grade products that Motion Asia Pacific will be stocking as part of their Food and Beverage package are the Diamond Stainless Steel Series chains.

AP SERIES (STANDARD CHAIN)

Provides the best balance between wear performance and corrosion resistance.

Well suited for food processing applications.

Uses 300 series (austenic) stainless components with precipitation hardened stainless steel pins.

300 SERIES

Designed specifically for applications requiring exceptional corrosion resistance, low magnetic permeability or that the chain be non-sparking.

Utilises only 300 series stainless steel components and pins.

Wear performance is the lowest of the stainless-steel material options.

400 SERIES

An application specific chain material, typically used only when there is exposure to a selected range of chemicals.