Frequent bearing failures on a mine site’s conveyor system pulleys prompted specialists from BSC and NSK to carry out joint investigations to discover the cause. The Australian mine had been replacing the bearings every year, with replacements causing unexpected delays in the mine’s operations.

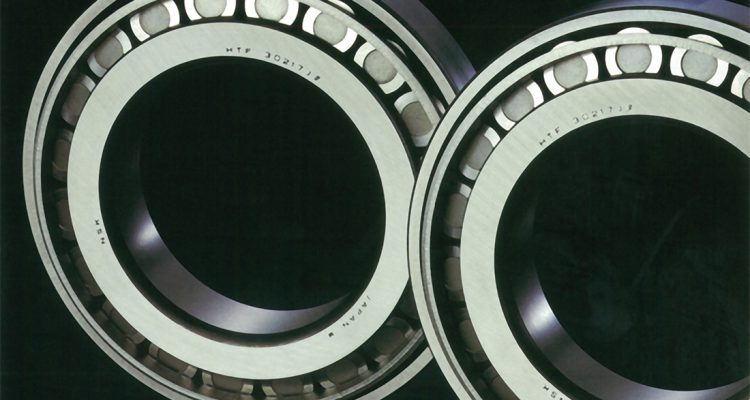

After conducting vibration analysis on the bearings, followed by subsequent inspections, the BSC-NSK team was able to confirm that the premature bearing failures were the result of excessive wear of the bearings’

outer races.

“As materials overflew on the conveyor belt, dirt particles entered the bearing and housing assembly through labyrinth seals. These hard particles then combined with the lubricants to form an abrasive paste. As the bearings were in operation, this abrasive paste wore the loaded zone of the outer races which resulted in premature failure,” explains Adam Chakraborty, Application Engineer at NSK Australia.

The solution proposed by the team was to replace the existing bearings with NSK’s Super-TF bearings – which feature superior outer ring strength compared to conventional bearings.

The mine has since been able to achieve service life of more than 2.5 years with the new NSK bearings, according to Adam.

Tony Tormey, BSC’s Product Manager for Industrial Bearings, says the NSK Super-TF bearings are a good solution for mine and quarry applications. “Contaminations are a fact of life when it comes to mining equipment,” says Adam. “About 50 to 60 per cent of the bearing failures we analyse throughout the year are caused by excessive contamination. This figure can reach as high as 90 per cent in highly contaminated applications”.

“NSK Japan’s engineering team response for such contaminated applications was to develop the TF Series of bearings, which includes the Hi-TF and Super-TF bearings and TL Series bearings. These bearings are manufactured using a special heat treatment process that alters the microstructure of steel, ensuring longer service life,” he adds.

“Equipment such as crushers, vibrating screens and conveyor systems on mine and quarry sites are exposed to high dynamic loads and contamination, which can reduce the bearing life considerably. The NSK Hi-TF and Super-TF bearings are ideal for such applications,” he says.

NSK Super-TF bearings can withstand higher shock and dynamic loads than conventional bearings. The international accredited registrar and classification society DNV GL has certified that when Super-TF material is used, the basic dynamic load rating can be improved by 23% in roller bearings and 26% in ball bearings.

“Super-TF stands for ‘Super Tough’ and this additional toughness in the bearing comes from a process known as carburization. By controlling the uniform fine distribution of carbide grains and retaining a certain percentage of austenite in the steel, the manufacturing process minimises the risk of surface and subsurface flaking which enhances the bearing’s resistance to stress,” Adam explains.

According to Adam, the NSK Tough Life (TL) series of bearings is another innovation by NSK that uses similar manufacturing techniques.

“The TL-series are designed to offer superior toughness for the inner rings, giving the bearings service life more than twice that of conventional bearings operating under conditions involving hoop stress.”

As the longest established bearings and power transmission distributor in Australia, BSC has been servicing Australian industries for the past 100 years. In addition to being a distributor for NSK’s products in Australia, the BSC technical team also shares a partnership with the NSK engineering team as a solution provider.

“It is important to understand the application characteristics and match the correct bearing to solve the problem. “By having BSC and NSK specialists visit the site, we ensure our customer is getting the right advice and the right bearing,” says Adam.

Tony says the Super-TF NSK bearings have been well-received by BSC’s mining clients in Australia.

“The BSC team is happy to work with NSK to introduce their unique bearing solutions to the Australian market. NSK’s TF technology is a solution that has come out of years of analysing the mechanisms of fatigue in bearings to help achieve longer component life. As NSK’s Australian distributors, we are proud to be a part of that growth and development.”