Enabling safer practices was first and foremost on their mind when CBC Australia established their own house brand Marlin Industrial Products to supply industrial consumables, including cleaning chemicals and materials handling equipment, to building materials manufacturers.

With their significant technical knowledge in keeping equipment and machinery in optimal working health, CBC noticed that understanding industry best practices and safety standards for different industrial products was a challenge for building materials manufacturers.

“Most sites have strict guidelines they have to follow for each product, for example, it’s essential that all products used for cleaning are completely safe,” Matthew Connors, Product Manager – Tools, Safety & Industrial Consumables says.

With full control of product sourcing and their supply chains, allowing for complete traceability from the manufacturing stage through to the end user, Marlin is able to guarantee that their product ranges adhere to all Australian guidelines, including the safety of their chemical cleaning products.

However, when cleaning a building materials manufacturing site, it can be a challenge to reduce the down time of machinery.

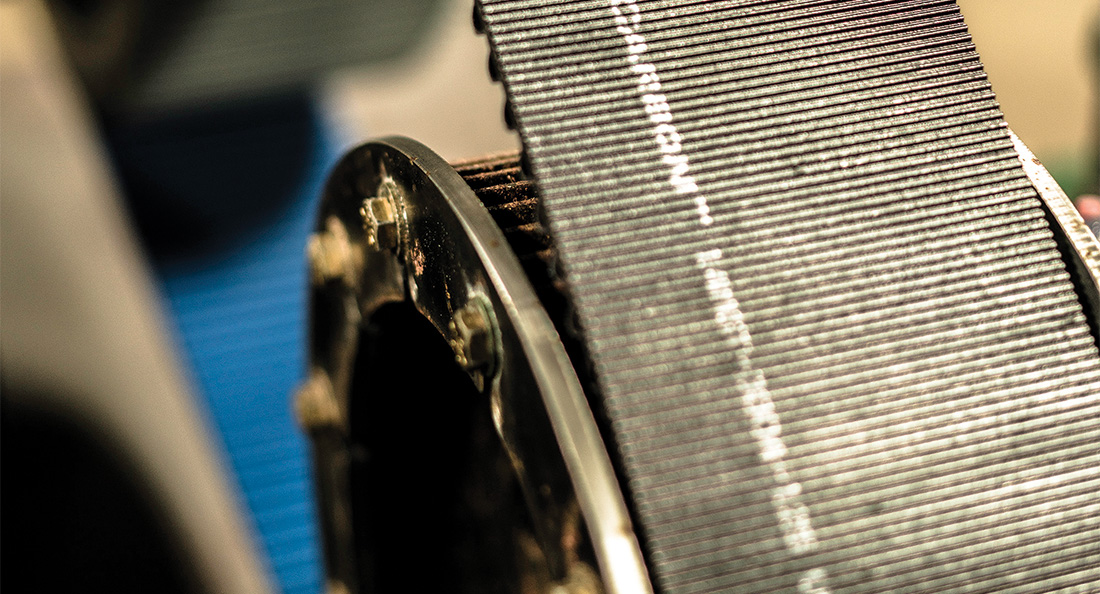

“We’re talking about companies that manufacture plasterboards, roof tiles, bricks, timber, so they’ve got either a semi-finished product or a finished product. You just can’t go onto a conveyor belt or a site like that and start spraying chemicals everywhere cause the interaction will affect the product that’s being manufactured and getting ready to be sold,” Wayne D’Souza, Market Segment Manager says.

Although Marlin chemical cleaning products are safe to use during operations, it is still necessary to stop building materials manufacturing operations for cleaning.

“You have to have the machines stopped, and no products on the conveyors or motors or gearboxes, to do a proper clean,” D’Souza says.

As such, Marlin products are fast-acting and chemically engineered to break down stubborn contaminants, including built-up dust, fibres, greases and oils.

Though the Marlin brand helps keep the equipment necessary for manufacturing healthy, it is just as much about the safety of site staff.

“It’s all about maintaining safe workspaces for people that work on the sites. Keeping workspaces and equipment clean and tidy and safe to use to improve visibility and identify any hazards which may occur like fluid spills, that’s key,” Connors says.

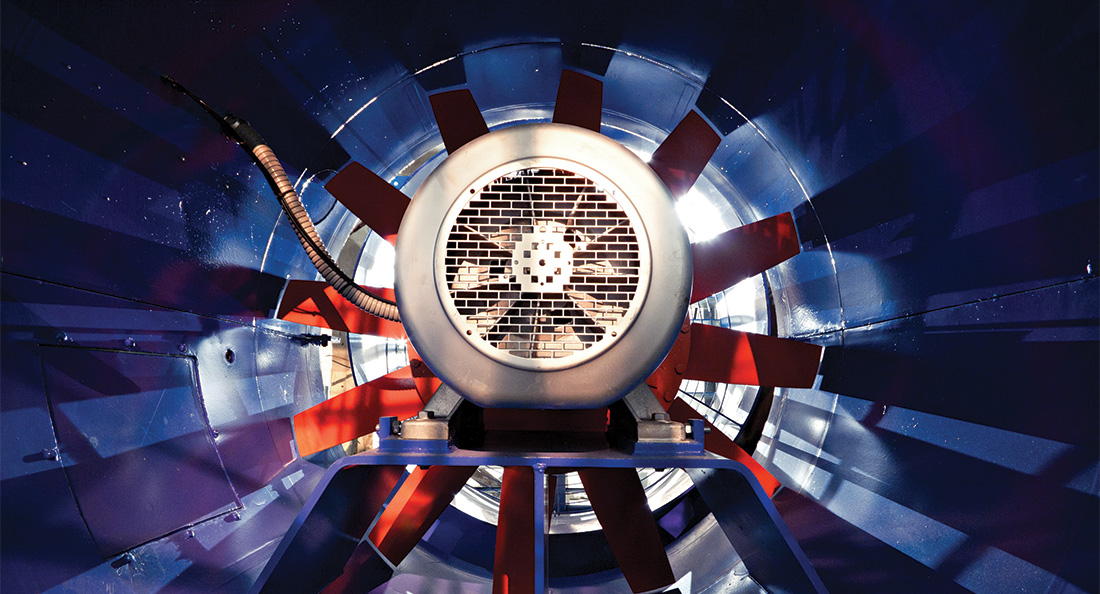

The second arm of the Marlin suite of products is materials handling equipment, which is intended to prevent injuries occurring and Occupational, Health and Safety issues from arising on site.

“In the building materials manufacturing industry, there are a lot of extremely heavy, awkwardly shaped products moving around at a high velocity. There are lots of equipment, lots of operators involved, and having the correct load restraint equipment that is properly labelled for the weight and the dimensions is essential,” Dominic Arena, Industrial and Engineering Consumables Category Manager says.

With CBC’s experience across a variety of industries – including mining, agriculture, food and beverage, and manufacturing – they are able to use their technical expertise to offer tailormade products in this category.

“Often a solution for one customer can then be applied to others in similar industry and we offer these solutions and recommendations as part of our service,” Arena says.

“We are able to offer customised solutions because we have that technical engineering product development capability, which differentiates us from the standard distributor who just walks in and sells right off the catalogue. We’ve got eyes and ears in the field that pick up on feedback and customer needs, and we’re able to develop products and product ranges that suit their requirements.”