Paper remains a crucial resource in our daily lives, serving numerous functions such as printing, packaging, mailing, publishing, and documentation. The paper industry is a significant employer in rural and regional areas of Australia, contributing to the growth and development of local economies. The sustainability of the paper industry is maintained by the implementation of circular approaches such as recovery and recycling operations, which positively impact the forestry and manufacturing sectors.

The dryer cylinders in a paper-making machine play a critical role in the paper production process. The controlled heat transfer process facilitated by these cylinders, promotes fibre bonding, and removes the remaining moisture from the paper. The steam-heated rolls that make up the dryer cylinders are one of the largest sections of the paper-making machine, each powered by an independent drive.

Motion representative Mark Bristowe and NSK collaborated several years ago to develop a long-term solution to a significant issue that a large Victoria-based paper mill was experiencing with its Dryer Cylinder Bearings. The TL (Tough and Long-life) Series spherical roller bearings were installed, resulting in longer change-out intervals and fewer machine breakdowns.

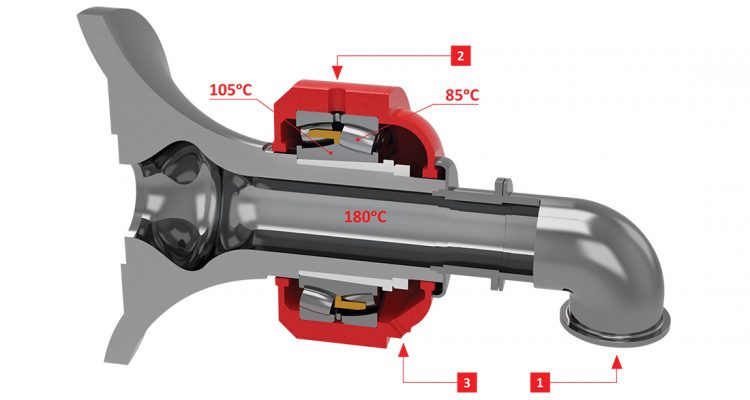

TL Series spherical roller bearings are specifically designed for components of papermaking machinery where elevated temperatures prevail such as Dryer Rolls. The bearings were developed as a solution to a specific problem relating to inner ring fractures. This problem is common on dryer cylinders where steam passes through the hollow axis of the roll to heat it.

High temperatures in Dryer Cylinder Rolls present challenges to bearings where the journal expands faster than the bearing, making the fit tighter and creating hoop stress. At the same time the presence of heat also lowers the viscosity of lubricant, severely effecting bearing life.

“The customer has been successfully using the TL Series Spherical Roller Bearing for a long time,” says Mark, who manages the BSC Sunshine branch. “I worked with NSK to implement this solution, which has resulted in lower maintenance costs and increased equipment reliability.”

Nitin Verma, General Manager Sales for Industrial Solutions at NSK, says that the inner ring cracking in spherical roller bearings is a common issue due to the high temperature variations within the bearing. To counter the effects of temperature, NSK analysed the mechanism of inner ring fracture and established a strength evaluation method that subsequently led to the development of the proprietary TL specification.

The bearings are now in service across five high-volume paper machines, with multiple sets of dryer cylindrical rolls on each machine slowly heating the paper web before trimming and finishing.

The TL spherical roller bearings are engineered to withstand even the most extreme temperature conditions while still delivering reliable and robust performance. They are designed to provide exceptional dimensional stability up to 200°C, ensuring they can operate effectively in the toughest of environments.

One of the key features of TL spherical roller bearings is their innovative design, which incorporates patented carburised bearing steel. This steel undergoes a special heat treatment to enhance wear resistance and longer lifespan even under the toughest operating conditions.

According to Mark, identifying the root cause of these vulnerabilities and applying extensive industry knowledge is where the collaboration between Motion and NSK excels.

“Our product experts are well-versed to address similar issues in a broad range of industries,” he says. “Because of the ongoing communication between our two businesses, customers can get answers to their engineering concerns and quickly implement solutions.”

Today, over 100 different TL bearing sizes/types are produced, helping a wide range of customers achieve better and more cost-effective performance. NSK can offer large TL series self-aligning roller bearings with outside diameters up to 1.36 metres.

Key features and benefits of TL Series Spherical Roller Bearings

- High-temperature resilience: withstand extreme temperatures up to 200°C for reliable performance.

- Innovative design: patented carburised bearing steel enhances wear resistance and lifespan.

- Specific solution: developed to address inner ring fractures in dryer cylinders caused by temperature variations.

- Longer change-out intervals: reduces maintenance frequency and downtime.

- Increased equipment reliability: minimises machine breakdowns for improved efficiency.

- Cost savings: lower maintenance costs and reduced bearing replacements.

- Robust performance: withstands demanding operating conditions in papermaking machinery.

- Broad application range: over 100 sizes/types available for better performance in various applications.