Various industries rely heavily on machines that work in unison to produce goods efficiently. When one machine malfunctions, it can bring the entire production line to a standstill. This is precisely what happened at a manufacturer of decorative surfaces, when their elephant stacker machine broke down. Harrison Hart, a WA-based Mechanical Engineer at Motion, was called in to troubleshoot the issue and provide a solution.

The business was initially hesitant at receiving engineering support, the customer had been using this specific machine for over forty years. Harrison outlined this was problematic because the machine had no up to date technical drawings and they had no knowledge about how to properly maintain it.

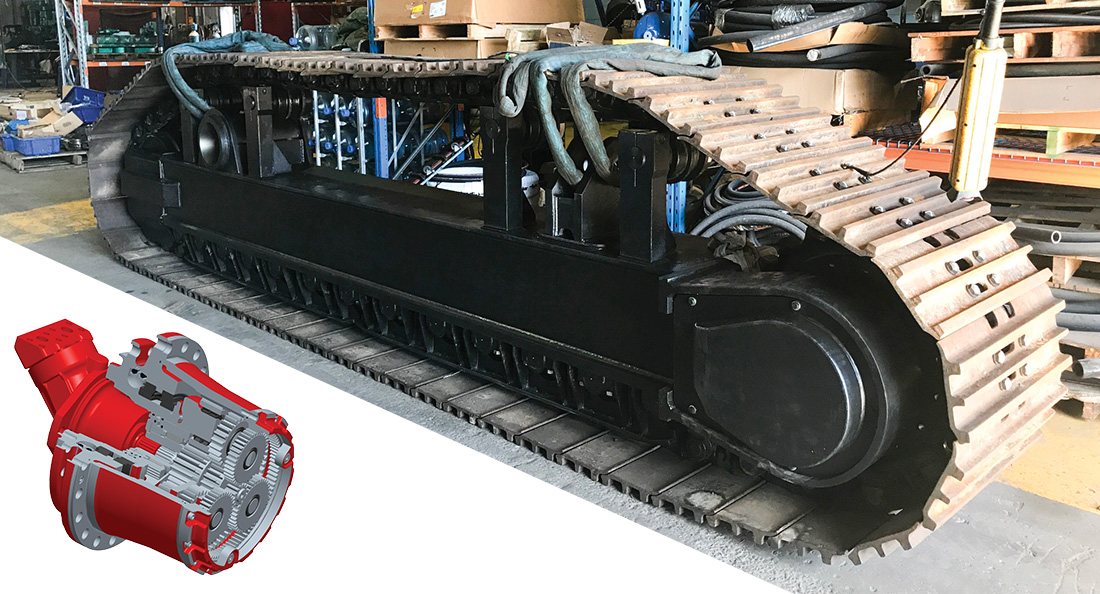

“The elephant stacker functioned as a rail-mounted carriage that was picking up stacks of particle boards, moving them around, and stacking them into piles” Harrison recounted. “The machine had multiple rail wheels with drives attached to them. On these drive systems were the gear sets that run the system.”

Harrison elaborated that the gear sets were getting destroyed every five or six weeks, forcing shutdown of the machine to replace the gears. This had a significant cost implication for the company, and halting production this frequently was having a huge impact on their production output. The company specialise in food and beverage preparation surfaces.

Upon investigating the issue, they discovered that the gear sets were not being maintained correctly. “The dry sawdust environment around the gearsets was not lubricated properly, leading to the constant destruction of the driveline.”

Lubricants are critical for keeping equipment running smoothly and efficiently in any industry, helping to reduce the impacts of wear and tear. Proper lubrication ultimately extends machine lifespan and improves the overall efficiency of machine operation.

With this in mind, Harrison and his team recommended appropriate spray-on gear lubricant, how to apply it, and the frequency of use which had a massive impact on their production.

He elaborated “we also went through and redrew the whole system, and on top of just redrawing it, we redesigned parts of it as well. The technical understanding we have now compared to forty years ago is completely different.” The engineering team’s intervention was health and safety informed, as machinery as old as this specific stacker could have posed a huge risk to workers at the plant. Redesigning parts of this machine would ensure risk levels are greatly decreased and the machine was more maintainable.

“With the recommended changes in place, the gear sets went from lasting only five to six weeks to lasting up to a year and a half,” Harrison discussed. This result proved the engineers’ technical understanding was essential.

Harrison explained that the role of Motion is to provide technical advice to customers and to be a trusted advisor in supporting the customer with their various needs. The expertise of the Motion engineering team adds value to the customer by being a reliable and knowledgeable resource, providing advice that people can follow regardless of their experience levels.

Another advantage of having access to engineering support is businesses can take a preventive approach when it comes to their machinery. Before machines run into problems in the first place, the engineering team can offer pre-emptive guidance. This proves invaluable in helping improve the running of a business.

The collaboration between the customer and Motion demonstrates the importance of technical expertise in offering valuable solutions. Motion’s engineers were able to solve a complex problem that had been plaguing the company for months, leading to improved efficiency, a reduction in downtime and according to Harrison, thousands of dollars in cost savings.

Harrison’s engineering solution is just a microcosm of some of the work that is being done in various industries. Motion can provide lasting solutions to completely turn a business around. As Harrison emphasised, “Motion’s role as a trusted advisor to its customers adds real value to their operations.”