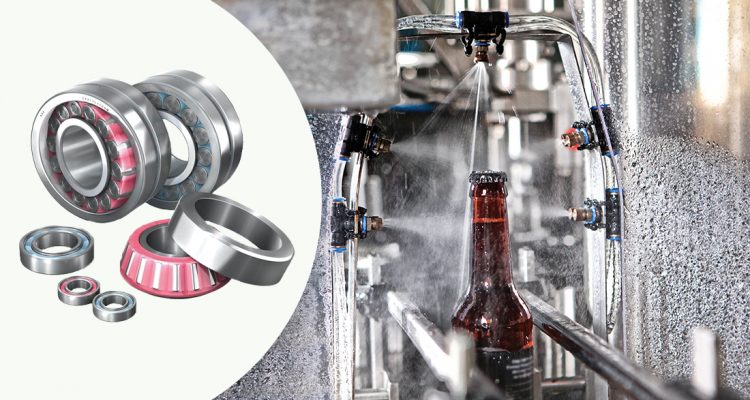

All food and beverage operations need to clean their equipment on a regular basis. Likewise, processing or production lines in food and beverage tend to use high-speed belts, which require bearings that can handle regular chemical washdowns.

NSK developed Molded-Oil™ Bearings for this purpose. They offer high performance in water and dust-contaminated environments. The Molded-Oil™ Bearings are lubricated with NSK’s oil-impregnated material, called Molded-Oil™ . It’s a lubricating oil and polyolefin resin with an affinity for oil. As a result, oil slowly seeps from this material, which provides plenty of lubrication to the bearing for extended periods.

Why do customers prefer these products?

Leon Stefanec is the National Business Development Manager for Food and Beverage at Motion. He’s been involved in the bearings industry for decades and understands the importance of using the correct bearings in the right situation. This is particularly the case when it comes to the dairy industry.

“It’s for longevity reasons,” said Stefanec. “The Molded-Oil™ Bearings outperform standard bearings. The main reason they outperform traditional bearings is because of the constant washdown that takes place in food and beverage operations. Your typical food processing plant will have chemical washdowns within their production areas two to three times a day.”

Those chemical washdowns come about for a variety of reasons. It might be a change of shift, a change of product – any number of issues could justify the chemical washdown.

“However, the chemicals are very harsh on bearings. Often, the staff use high-pressure cleaners to eliminate as much detritus as possible from their equipment. The high-pressure cleaners will displace the grease from conventional bearings, which will then be replaced with water. Water will fill that cavity and push the rest of the grease out,” says Stefanec.

He pointed out that the grease is suspended in a polyolefin resin in the Molded-Oil™ Bearings. As a result, the lubricant cannot be dislodged, which means the bearings last significantly longer than conventional bearings.

Tony Tormey, the Category Manager of Industry Bearings at Motion, has been working with bearings and things that spin for nearly twenty years. Tormey gets the importance of keeping bearings properly lubricated to keep them in good condition.

“One of the biggest benefits of Molded-Oil™ Bearings is the continuous supply of lubrication oil as the bearing runs. That makes it a maintenance-free bearing. You generally get twice the lifespan compared to a standard grease-lubricated bearing when working with a Molded-Oil™ Bearing,” said Tormey.

Tormey explained that this is because of the lack of contamination that would normally destroy or emulsify the grease.

“If you have a lot of water in your manufacturing process, the water ingress will emulsify the grease,” he said. “The Molded-Oil™ Bearing eliminates the problem entirely.”

How do customers tend to use these bearings?

Leon explained that maintenance teams prefer the Molded-Oil™ Bearings for two broadly different reasons. One is their ability to handle washdowns. The other is because they don’t require maintenance – an attribute that is particularly helpful in context of where the bearings are located.

“Bearings in food and beverage applications may be tough to access,” he said. “The teams might need scissor lifts or other specialist equipment to get to that section of the plant. Maintenance teams dislike having to change the bearings on anything in those parts of the plant. It’s dangerous and time-consuming. That’s another reason why they would choose the Molded-Oil™ Bearings in such applications.”