Whether it’s out in the field, or at a processing plant, onsite drilling and cutting processes are common practices for site engineers and maintenance, repair, and operations specialists. During peak harvest and planting seasons, MROs are kept busy with necessary maintenance and repairs to farming equipment and machinery – and time is always of the essence. Onsite drilling, hole-making, and threading can be a time consuming and arduous task that requires the right power tools to get the job done.

This is not just a tool, it’s a game changer

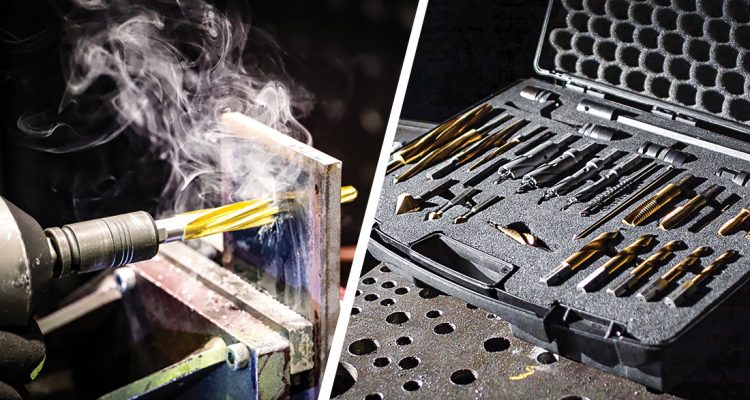

Introducing the Alpha VersaDrive – The world’s first modular quick-change cutting and drilling system. Specially designed for use on cutting and drilling tools across multiple tool platforms such as impact wrenches, drills and drivers, rotary drills, magnetic-based drills and pillar drills.

Revolutionising traditional work practices

Alpha has revolutionised onsite cutting and drilling processes with their range of Alpha VersaDrive sets, including impact starter kits, tapping kits and installation kits as well as imperial and metric sets that cater to a wide range of applications and industries. The non-slip 11.0mm hex shank design fits into all standard drill chucks and has three concentric lock positions allowing perfect alignment and accuracy when tooling with any of the modular adaptors.

Cut costs. Save time. Increase productivity.

Investing in Alpha VersaDrive removes the challenges of onsite drilling, hole-making and threading in one easy system. Custom-engineered quick-change adaptors connect the tool platform to any one of the Alpha VersaDrive attachment tools. The high-grade steel tool attachments have been specifically designed to outperform the closest comparable products on the market, producing up to 15 times faster results, longer life, and more holes per product.

What Alpha VersaDrive customers are saying

“We had a large fabrication project which required high precision with very low working tolerances. After processing and galvanising, a range of holes that required precise alignment fell outside of working tolerance. We were looking at a complete remake or arduous manual rework of the parts involved, which would have incurred substantial costs.

Thankfully, we came across the Alpha VersaDrive reamer bit that allowed us to open up the misaligned holes accurately and quickly to a point where they could function as intended.

The Alpha VersaDrive reamer changed a job that would normally take us a week into a job that took a day. We highly recommend this product for anyone in the metalworking industry who is looking for an efficient and speedy way to solve a problem.” – Alliance Metal Solutions

We can guarantee that you have never seen anything like this before, Alpha has revolutionised onsite cutting and drilling processes. Imagine looking up at a communications tower knowing you need to drill some precisely aligned 4x14mm holes to attach a bracket. You need to climb up with a 12kg magnetic-based drill, drill the hole and then work out how to thread it. It’s heavy and dangerous work. Then along comes the Alpha VersaDrive, and suddenly your job gets a whole lot easier, and quicker. When you get to the top of the tower with your Alpha VersaDrive kit you can now use your standard, portable power tools to get the job done fast and most importantly, safely.

If you are interested in learning more about the Alpha VersaDrive range, you can contact your local Motion branch to speak to a technical representative about purchasing or bulk ordering Alpha VersaDrive products. You can also view the full range of Alpha VersaDrive products at www.alphatools.com.au